Contents

What are clothing packaging bags?

Garment packaging bags are soft containers used to package and protect clothing products. They are usually made of plastic, compostable materials, degradable materials, paper, cotton, linen or other materials, and are designed to be in direct contact with clothing to keep them clean, wrinkle-proof, dust-proof, moisture-proof, and provide protection during transportation and storage. The design and material selection of clothing packaging bags take into account not only practicality but also aesthetics, as they are often used as part of brand promotion to enhance brand image and product appeal by printing brand logos, patterns or information.

Types of clothing packaging bags

The types of clothing packaging bags commonly used by clothing factories are mainly the following:

Recyclable PE packaging bags (PCR)

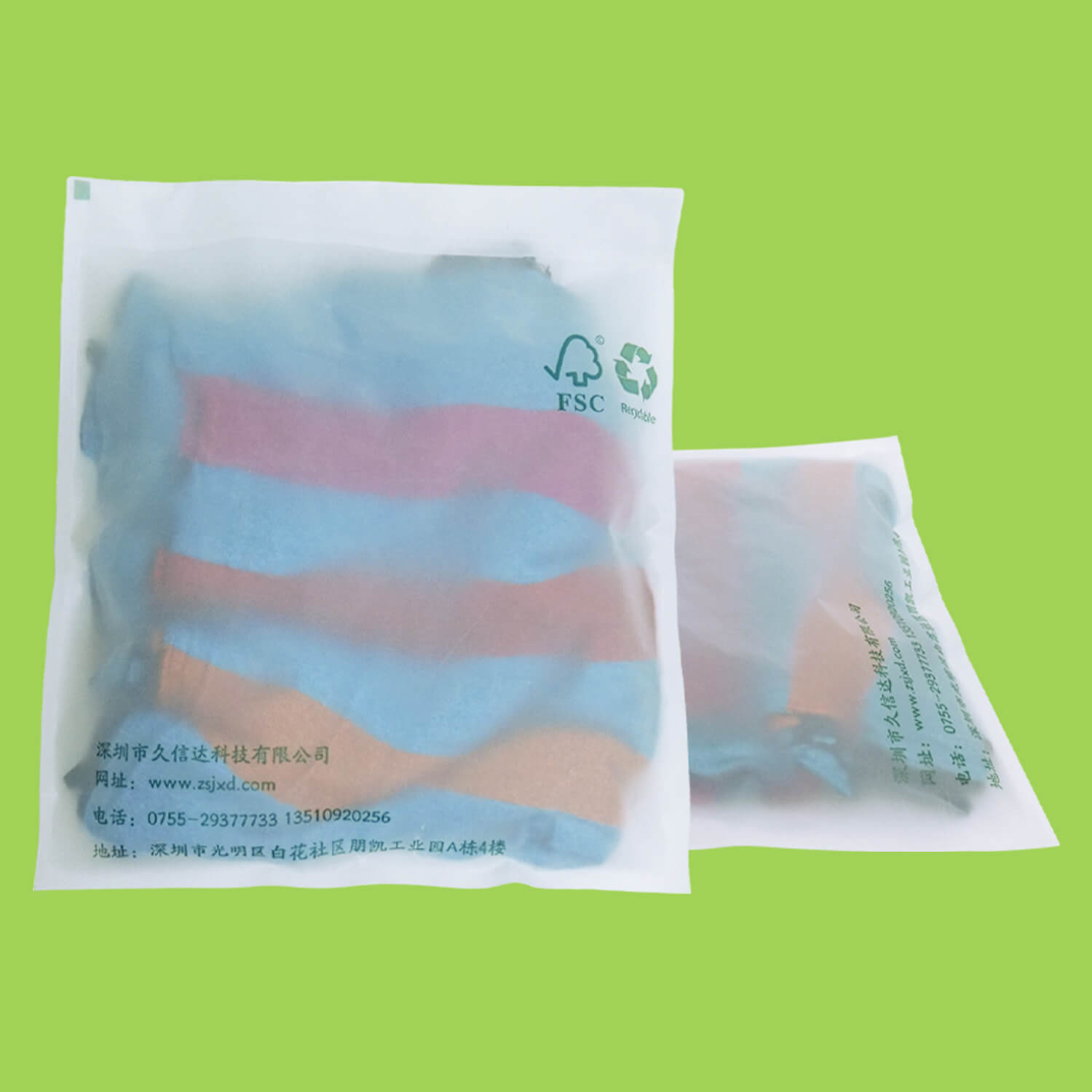

Recyclable PE (polyethylene) packaging bags for clothing, commonly known as PCR (Post-Consumer Recycled) bags, are packaging bags made from polyethylene materials recycled after consumption. The core advantage of such bags lies in their environmentally friendly characteristics, as they reduce the demand for new plastic raw materials while reducing the burden of waste on the environment by reusing waste plastics. PCR bags maintain the lightweight, durable and waterproof properties of PE materials, are suitable for protecting clothing from pollution and moisture, and can be transparent or translucent to facilitate the display of clothing inside the bag.

Environmentally friendly paper bags

Environmentally friendly paper bags are usually made of kraft paper, recycled paper or other sustainable sources of paper, which not only reduces the impact on the environment, but also enhances the brand’s market appeal and consumer experience through its natural texture and customizable printed design. Environmentally friendly paper bags have become a popular choice for the apparel industry in packaging due to their durability, lightness and potential to carry brand information, and also reflect the brand’s commitment to sustainable development and environmental responsibility.

Self-adhesive bags

The core features of this type of bag are its convenience and practicality. They are usually made of plastic or other lightweight materials and have a self-adhesive closure design. The design of the self-adhesive bag allows the clothing to remain neat and wrinkle-free after packaging, while making it easy for consumers to identify and view the product. The self-adhesive strip at the closure ensures that the bag remains closed during carrying, preventing the clothing from falling or being damaged.

Resealable bags

Resealable bags in clothing packaging are a packaging solution designed for multiple uses. Their core advantages are durability and convenience. This type of bag is usually made of high-quality plastic or other synthetic materials, with a resealable mechanism such as a zipper closure or adhesive closure strip to ensure that the bag can be easily reclosed after use.

Flat Bag

Clothing Packaging Flat bags are a simple and classic form of packaging. They are usually made of materials such as paper or plastic and have a flat rectangular shape. This type of pocket has a simple design and is usually used to package clothing packaging such as shirts and T-shirts. It is easy to mass produce and cost-effective. The opening of the flat bag is usually closed by folding, gluing or stapling to ensure the safety and neatness of the clothing during transportation and storage.

How to Customize Clothing Packaging Bags

Customizing clothing packaging bags is a multi-step process involving design, material selection, production and quality control. First, you need to determine the purpose and target market of the packaging bag, which will affect the type of materials and design elements you choose. For example, if your clothing brand is positioned in the high-end market, you may choose higher quality materials and sophisticated designs.

Next, you need to design the appearance of the packaging bag. This usually includes determining the size, shape, color, weight scheme, and any printing or pattern. The design should reflect your brand image and attract target consumers. You can work with a professional designer or design it yourself using design software.

When it comes to material selection, you can decide what type of material to use based on environmental requirements and cost-effectiveness. Common choices include non-woven fabrics, biodegradable, compostable, cotton, paper, or recyclable plastic. Each material has specific properties, such as durability, sealing, waterproofness, and environmental protection.

Once the design and materials are determined, you can contact a professional packaging bag manufacturer to produce customized packaging bags. Before production, the manufacturer will usually provide a sample or prototype for you to check and approve. This is a key step to ensure that the final product meets your expectations.

Customized clothing packaging bags can not only enhance the brand image and enhance the consumer’s shopping experience, but also be a way to show your commitment to environmental protection.