Synthetic polymer materials can be rapidly developed and applied because their functions and properties can be regulated or even customized through chemical structure design and relative molecular mass regulation. In modern society, synthetic polymers are widely welcomed due to their customizable performance, low price, easy to synthesize and other advantages.

The vast majority of commercialized polymers currently come from fossil fuels such as oil, coal, natural gas and shale gas, and the non-renewable resources used in the production of plastics account for about 7 per cent of global oil and gas. However, fossil resources are finite and many studies predict that all fossil resources will be depleted within a few centuries. In addition, the stability and durability of petroleum-based polymers make them difficult to degrade in the environment, and a large amount of plastic waste exists in the form of garbage. The low density of the material allows it to occupy a high volume fraction of the buried waste, creating a serious white pollution problem and accelerating the depletion of landfills, so the disposal of the final plastic waste is still a major problem plaguing human society.

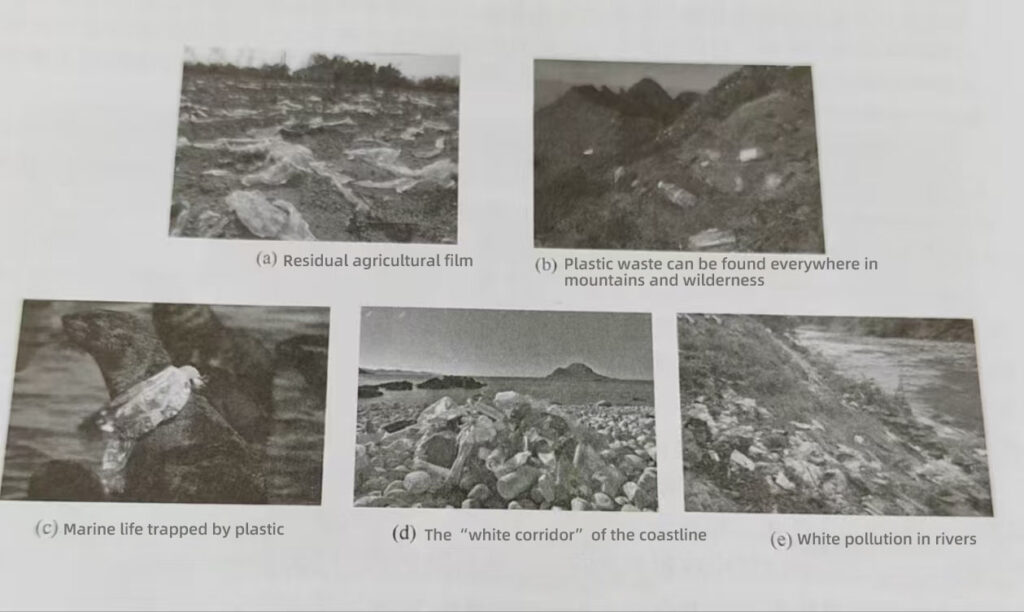

Figure 1-1 lists some common cases of environmental pollution, which will become more and more serious if relevant measures are not taken to control and solve them. In recent years, the rise of the plastic recycling industry has reduced the negative impact of synthetic polymer materials on the environment to a certain extent, but the difficulty of efficiently collecting and classifying plastic waste, the multi-component nature of plastics, and the deterioration of the performance of recycled plastics have all severely limited the recycling of plastics.

soil contamination

Figure 1-1 White Pollution Cases

The realistic urgency of building an ecological civilization, the enhancement of environmental awareness and the proposal of green economy have prompted people to look for environmentally friendly synthetic polymer materials on the one hand, and to explore the development of new processes for extracting natural polymers from sustainable and renewable raw materials; on the other hand, they have taken measures to minimize the environmental hazards caused by polymer materials. In order to solve this problem, biodegradable polymer materials have entered people’s vision. Biodegradation of polymer materials occurs through the decomposition of microbial enzymes such as bacteria and fungi, and the structural integrity of the polymer material is destroyed by the sharp decrease in relative molecular mass. Despite the generally high relative molecular mass and inherent inertness of polymeric materials, it has been proven that it is possible to synthesize and prepare polymers that can be substantially degraded in a short period of time. The first generation of biodegradable materials consists of polymers mixed with materials that are easily consumed by emblematic organisms. In general its not fully biodegradable. The classic example is a mixture of starch and polyethylene manufactured as a partially biodegradable bag. The second generation is the attempt to introduce functional groups (e.g. ester bonds) in the polymer backbone that are susceptible to microbial action. Typical representatives of this type of material are, for example, polyethylene terephthalate (PET) used in the manufacture of flower pots and polybutylene terephthalate-adipate-butylene terephthalate (PBAT) used in the preparation of fibers. The third generation consists of materials such as bacterial cellulose and polyhydroxybutyrate (PHB), which are naturally synthesized by bacteria grown in fermentation tanks. Current research has concluded that ideal biodegradable polymer materials require, in addition to biodegradability, that their degradation products be non-toxic and have suitable mechanical and processing properties as well as economic feasibility.