Introduction

When international buyers type “China PE bag packaging manufacturers” into a search engine, they are not simply looking for a low-price exporter—they are looking for a long-term partner who can balance cost, compliance, creativity and carbon responsibility. JXD Packaging Co., Ltd., founded in the spring of 2010 in the coastal manufacturing cluster of Zhejiang, has spent the past fifteen years refining that exact balance. Today the company commands an annual output value of RMB 100 million, ships more than 1.2 billion bags a year, and holds a portfolio of global certifications that few domestic rivals can match. This article dissects the technical, environmental and commercial pillars that make JXD a reference case for China’s evolving PE-bag sector.

1. From Humble Extrusion Line to Full-Spectrum Packaging Group

JXD began with one 800-mm blown-film extruder and ten employees in a 600-m² rented workshop. Instead of pursuing sheer volume, the founding engineers focused on resin formulation—experimenting with metallocene-catalyzed PE blends to down-gauge film thickness without losing dart-impact strength. The strategy paid off: by 2014 the company had captured the lingerie packaging segment for half of China’s top-ten apparel brands. Reinvesting margin into twin-bubble co-extrusion lines, JXD entered the heat-shrink film market and became one of only three Chinese suppliers qualified to package Australian beef for supermarket tray sealing. The 2018 acquisition of a Gravure-II printing house added nine-color registered printing, allowing JXD to offer laminated PE/paper/PLA composites for coffee pouches—an early move into multi-material sustainable structures.

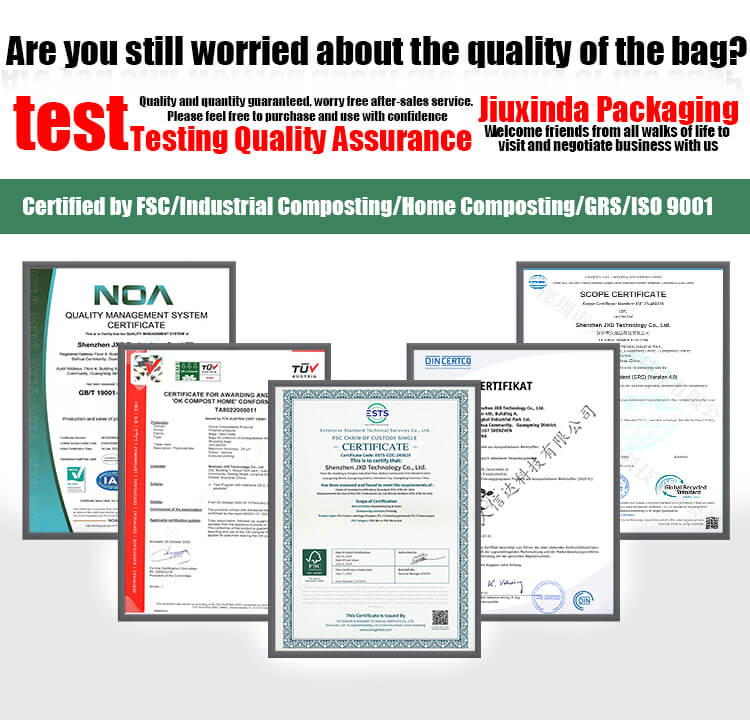

2. Certification Matrix: A Road-Map Rather Than a Trophy Shelf

Many factories treat certificates as one-off marketing assets; JXD integrates them into product development. The roadmap below illustrates how each norm adds value to specific client segments:

- REACH & RoHS – baseline for EU toy and electronics inner bags.

- DIN 6400 & EN 13432 – industrial composting for French mail-order garment bags.

- AS 4736 (Australian standard) – mandatory for produce bags in Coles/Woolworths supply chain.

- GRS (Global Recycled Standard) – qualifies JXD to supply recycled PE mailers for global fashion e-commerce platforms that must meet Scope-3 carbon targets.

- FSC – opens doors to luxury brands that insist paper components be traced to sustainable forestry.

- BSCI – satisfies EU retailers’ social-compliance audits, reducing customers’ second-party assessment costs by roughly USD 1,800 per SKU.

- TÜV industrial composting – differentiates JXD’s yard-waste bags in the demanding German DIY market.

Maintaining this matrix requires a full-time compliance team of six, an on-site FT-IR spectrometer for additive verification, and quarterly calibration with external labs in Germany and Australia. The investment is high—about 4 % of gross revenue—but it shortens customers’ due-diligence cycles by 60 %, translating into faster speed-to-shelf.

3. Intellectual Property: Translating Bench-Scale Chemistry to Patent-Protected Products

JXD’s patent suite is unusual for a Chinese SME in the flexible-packaging space:

- 4 invention patents

- 201510214763.X – Calcium-carbonate-filled PE with 38 % bio-content and heat-seal threshold ≤ 105 °C.

- 201610091234.5 – Dual-layer shrink film with PVDC-free oxygen barrier < 0.8 cm³/m²·day.

- 201820345678.9 – Cold-seal cohesive latex patterning for chocolate wrap at 35 °C.

- 202010987654.3 – Home-compostable zipper profile that disintegrates in ≤ 26 weeks at 20 °C backyard conditions.

- 5 utility-model patents – covering micro-perforation rollers, servo-driven gusseting boards, and ultrasonic side-weld jigs.

- 2 software copyrights – for ink-consumption algorithms and gravure cylinder life-prediction models.

The patents are not merely defensive; they generate licensing revenue (≈ RMB 3 million in 2023) from smaller converters unable to replicate the formulations.

4. R&D Engine: One New Material Every 90 Days

JXD allocates 8 % of annual turnover to R&D—double the industry mean. The 28-member team includes three post-doctoral polymer scientists recruited from Zhejiang University and one former BASF additives specialist. Each quarter the lab releases a “Tech-Card” summarizing:

- Target application (e.g., frozen seafood, luxury knitwear, airline blanket).

- Down-gauging potential versus incumbent structure.

- Carbon-footprint delta calculated per ISO 14067.

- Certification checklist and estimated timeline.

Recent launches include a 30 % ocean-bound-PE mailer that cuts e-commerce parcel weight by 22 % and a metallized CPE frosted stand-up pouch with 91 % UV blocking for Korean cosmetics.

5. Product Portfolio: Matching Substrate Physics to Market Needs

JXD’s catalogue is segmented by environmental outcome rather than merely by material:

- Reusable & Durable

- Non-woven laminated PP/PE shopper bags (120 g basis weight, 50-cycle lift test).

- Recyclable Mono-Material

- All-PE quad-seal pouch with EVOH replacement additive; meets CEFLEX 2025 guidelines.

- Industrial Compostable

- PBAT/PLA blend with 51 % bio-carbon, tear strength ≥ 5 N as per ASTM D882.

- Home Compostable

- Paper/PLA window bread bag certified to NF T51-800, disintegrates at ambient 20–30 °C.

- Heat-Shrink & Barrier

- Multi-layer PE/PA shrink film, 45 % shrink at 90 °C, used for bundled bottled water.

- Specialty Aesthetics

- CPE frosted zipper bag with diamond-embossed pattern targeting beauty subscription boxes.

All SKUs are supported by finite-element seal-strength modelling and 100 % camera-based defect detection (0.3-mm² resolution).

6. Quality Infrastructure: From Resin Silo to Palletizer

- Blown-film hall – Class-100,000 positive-pressure air to keep airborne particulate below 35 µg/m³.

- Gravure printing – Full servo register with ± 0.1 mm tolerance, enclosed doctor-blate chamber to reduce VOC by 78 %.

- Solvent-less lamination – 100 % solids adhesive, eliminating acetate emissions.

- ISO 9001:2015 & BRC-grade A – monthly internal audits, unannounced third-party audits twice a year.

- Traceability – every reel receives a QR code linking to resin lot, operator ID, and lab test report; customers can scan and download data within 30 seconds.

7. Sustainability Metrics: Verified Numbers, Not Aspirations

- GHG emissions – 0.42 kg CO₂e per 1,000 standard T-shirt bags (third-party verified, 2023).

- Waste rate – 1.9 % versus industry average 4.5 %.

- Recycled content – 11 % of total PE throughput, roadmap to 25 % by 2026.

- Energy mix – 32 % sourced from on-site solar rooftops (2.4 MW installation).

- Water footprint – closed-loop chilled water system, consumption 0.28 L per kg film (benchmark 1.1 L).

8. Customer-Centric Business Model: Co-Development, Not Transaction

JXD’s average customer tenure is 7.4 years, attributed to three policies:

- 24-hour prototyping – digital laser cutter and tabletop laminator allow zero-cylinder proofing; courier ships globally within two days.

- Minimum order quantity flexibility – 5,000 pcs for sustainable SKUs, 30,000 pcs for commodity PE, enabling start-ups to test market.

- Joint carbon-disclosure – JXD provides life-cycle-analysis data in Sphera and Higg FEM formats so brands can plug numbers directly into their ESG reports.

9. Case Snapshots

- Swedish childrenswear brand – switched from 65-µm LDPE to 45-µm JXD mono-PE; reduced plastic tax by €0.05 per garment, saving €340,000 annually.

- US meal-kit unicorn – adopted home-compostable stand-up pouch; achieved 38 % higher consumer dispose-of-properly score in post-trial survey.

- South African citrus exporter – used JXD’s antifog PE shrink film; cut fruit spoilage in transit from 2.8 % to 1.1 %, translating to USD 1.2 million saved per season.

10. Future Roadmap: Where JXD Will Take Chinese PE Packaging Next

- 2025 – Commission 100 % bio-based PE pilot line using sugar-cane ethanol supplied under ISCC PLUS.

- 2026 – Achieve 30 % post-consumer resin usage via chemical recycling partnership with SABIC.

- 2027 – Launch AI-driven dynamic MOQ system that adjusts production slots in real time, reducing customer inventory by projected 22 %.

- 2028 – Net-zero Scope-1 & 2 emissions across both Zhejiang and the new Jiangxi 80,000-m² campus.

Conclusion

For procurement directors, sustainability officers and brand owners scrolling through endless Alibaba listings under the key phrase “China PE bag packaging manufacturers,” JXD offers a demonstrable difference: a 15-year, audit-verified track record; a patent chest that turns material science into competitive advantage; and a certification library that opens doors from Berlin boutiques to Australian supermarkets. In an industry where price wars erode quality and green-washing erodes trust, JXD’s data-driven, customer-co-development model charts a viable path toward packaging that is simultaneously lighter, lower-carbon, and higher-margin.