Introduction

The global apparel industry is undergoing a paradigm shift toward sustainability, and packaging is no longer a mere after-thought. Consumers, governments, and brands now demand packaging solutions that protect garments while protecting the planet. Among the manufacturers leading this transformation is JXD, a company whose story began in the spring of 2010 and whose 15-year trajectory has been defined by technical ingenuity, rigorous certification, and an unwavering commitment to environmental stewardship. With an annual output value exceeding 100 million yuan, JXD has positioned itself as a strategic partner to fashion labels seeking eco-responsible packaging without compromising on design, durability, or supply-chain transparency.

Heritage & Scale

Founded at a time when “green packaging” was still a niche concept, JXD invested early in specialized extrusion lines, solvent-free lamination towers, and closed-loop recycling systems. Today, the company operates a 45,000 m² integrated campus that houses R&D laboratories, pilot-scale compounding workshops, and Class-100,000 clean-room converting halls. Three fully automated blown-film lines run 24/7 to meet peak seasonal demands, while a just-in-time digital warehouse system synchronizes raw-material inflow with customer forecasts across four continents. The result is a production capacity that exceeds 250 million bags per year while maintaining a reject rate below 0.3 %—a figure that rivals semiconductor-grade quality standards.

Certifications that Command Trust

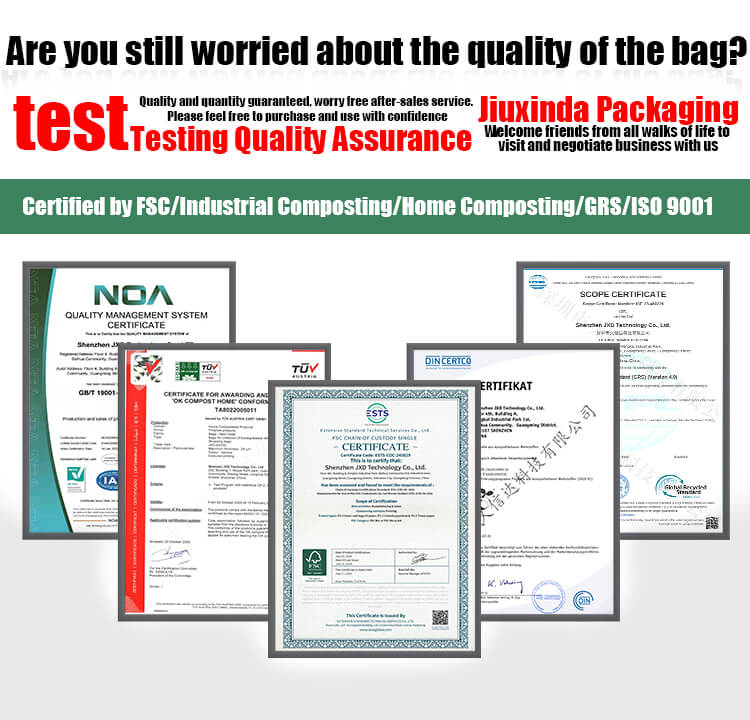

JXD’s packaging portfolio is backed by one of the industry’s most exhaustive certification matrices:

- Chemical Safety: REACH and RoHS compliance guarantees that every resin, ink, and adhesive is free of SVHCs (Substances of Very High Concern).

- Biodegradability & Compostability: DIN 6400, EN 13432 (both industrial and home composting), and AS 4736 (Australian standard) validate complete disintegration within 90–180 days without eco-toxic residue.

- Circularity: GRS (Global Recycled Standard) ensures traceability of post-consumer recycled (PCR) content; FSC-certified paper elements originate from responsibly managed forests.

- Social Accountability: BSCI audits confirm ethical labor practices across the supply chain.

- Third-party Verification: TÜV Austria and DIN CERTCO provide annual surveillance audits and issue compostable logos that are instantly recognizable to regulators and end-users.

These credentials enable JXD’s customers to enter restricted markets—such as the EU Single-Use Plastics Directive zone or Australia’s APCO program—with minimal regulatory friction.

Innovation Pipeline: Patents & New Materials

Innovation at JXD is not episodic; it is institutionalized. The company allocates 8 % of annual revenue to R&D and retains a cross-disciplinary team of polymer chemists, fiber engineers, and packaging designers. Their efforts have yielded:

- Four invention patents, including a proprietary starch-PLA hybrid resin that cuts carbon footprint by 42 % compared with virgin LDPE.

- Five utility model patents, among them a micro-perforated venting channel that reduces garment wrinkling during vacuum packaging.

- Two software-based soft-package patents that integrate NFC tags for supply-chain traceability without compromising recyclability.

Each year, the R&D cell introduces at least two new substrate families. Recent launches include algae-based TPU films for high-stretch activewear bags and mono-material PE/PE pouches that enable full-stream recycling in jurisdictions with store-drop-off programs.

Product Portfolio at a Glance

JXD’s catalog is deliberately broad, recognizing that apparel packaging must serve functions ranging from point-of-sale aesthetics to e-commerce damage reduction.

- Non-Woven Fiber Bags

Spun-bond or stitch-bond polypropylene alternatives made from 60 % sugarcane-derived bio-PP. Customizable GSM (60–150 g) and ultrasonic-welded handles ensure load-bearing up to 12 kg.

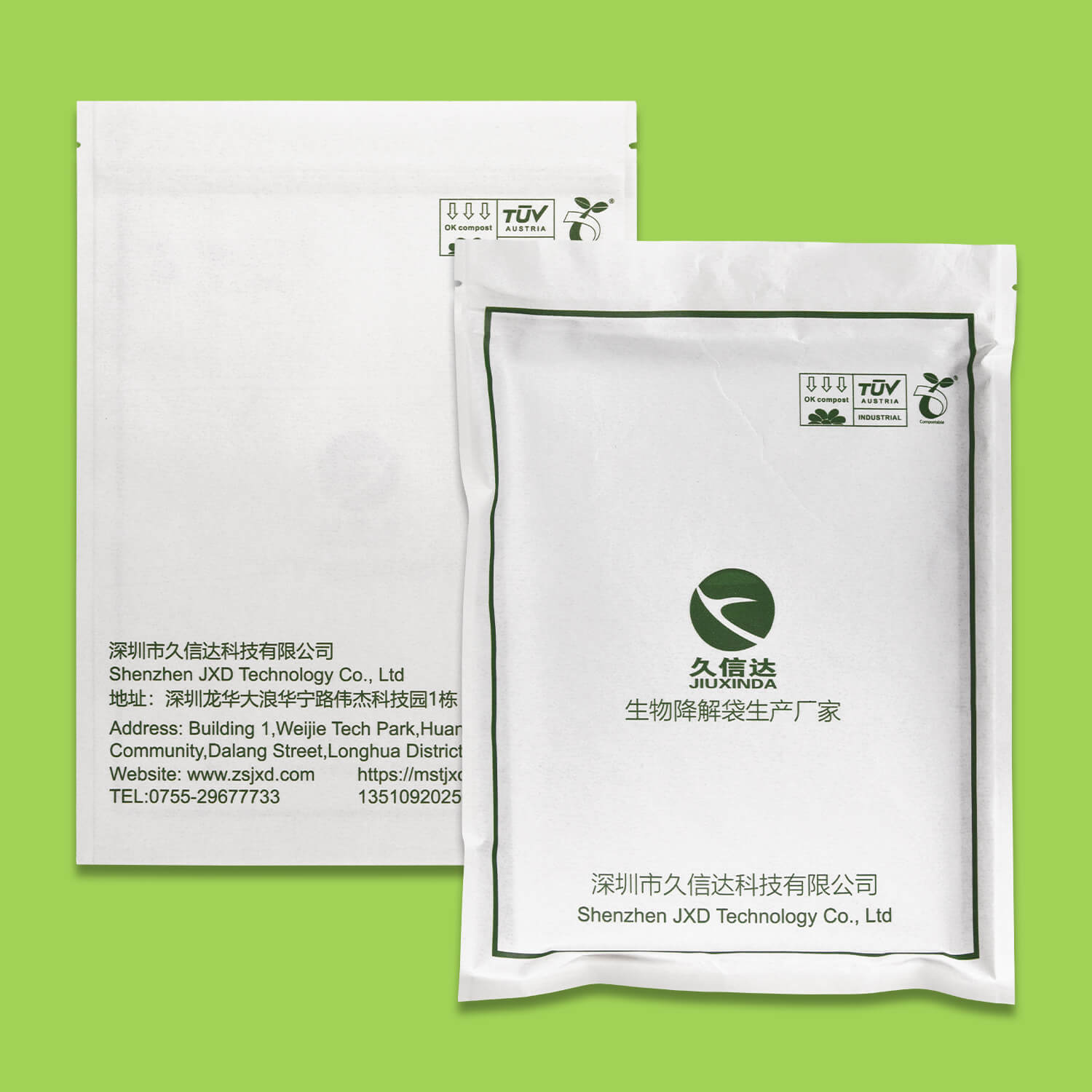

- Biodegradable & Compostable Bags

PLA, PBAT, or PBS blends certified for both industrial and home composting. Optional matte or glossy finish, water-based inks, and zipper closures made from identical resin for mono-material disposal.

- Eco-Friendly Paper Bags

FSC-certified kraft or art paper laminated with a micro-thin PLA window. High-resolution flexographic printing supports 8-color photographic imagery, while water-borne adhesives eliminate VOC emissions.

- Recyclable Plastic Bags

30–100 % PCR-LDPE or PCR-HDPE, optimized for store-drop-off recycling streams. Side-gusseted designs accommodate bulky winter coats; mineral-additive formulations reduce resin use by 15 %.

- CPE Frosted Bags

Cast-polyethylene with soft-touch matte surface, ideal for luxury lingerie or athleisure. Anti-static additives prevent dust attraction during long-haul freight.

- Heat-Shrink Bags

Multi-layer co-extruded POF (polyolefin) with 60 % cross-direction shrinkage, providing tamper-evidence for boxed shirts or denim sets. Perforation patterns allow controlled air evacuation to minimize package volume. - Composite Bags

PET/AL/PE or OPP/VMPET/PE structures for moisture-sensitive garments such as silk or down jackets. Optional high-barrier EVOH layer extends shelf life in humid climates. - Inner Packaging Accessories

Zip-lock pouches for buttons and spare sequins, anti-tarnish films for metallic trims, and garment-shaped die-cut inserts that reduce folding lines.

Customer-Centric Philosophy & Service Architecture

JXD’s business philosophy—“Prioritize the customer; elevate quality service”—is operationalized through three pillars:

- Co-Creation Studios

Brands can co-develop bespoke structures in JXD’s pilot plant within 72 hours, leveraging digital twin simulations to predict seal strength, drop-test resilience, and shelf appeal. - Zero-Defect Program

Statistical process control (SPC) charts track critical variables such as seal temperature, film thickness, and ink viscosity in real time. Any deviation triggers an automatic hold-quarantine loop, ensuring that no defective roll leaves the facility. - Sustainability Dashboards

Customers receive quarterly LCA (life-cycle assessment) reports aligned with ISO 14040/44 and GHG Protocol scopes 1, 2, and 3. The dashboard quantifies CO₂-e savings achieved versus conventional packaging, enabling brands to meet Science-Based Targets (SBTi) commitments.

Industry Applications & Case Studies

- Fast-Fashion Retailer (Europe)

JXD converted 45 million poly-mailers to 80 % PCR-LDPE with a tear-strip for re-use, cutting virgin plastic by 360 t/year and reducing packaging tariffs under the EU Plastic Packaging Tax. - Outdoor Apparel Brand (North America)

A switch to home-compostable garment bags eliminated 22 t of landfill waste during the 2023 fall season and earned the brand a feature in REI’s “Opt to Act” campaign. - Luxury Lingerie Label (Asia-Pacific)

Custom CPE frosted bags with soft-touch varnish elevated unboxing experience, driving a 17 % increase in social-media mentions and a 9 % uplift in repeat purchases.

Future Outlook

Looking ahead, JXD is piloting a blockchain-enabled resin traceability module that will allow consumers to scan a QR code and view the entire journey—from sugarcane field to closet. Concurrently, the company is scaling a closed-loop take-back program in partnership with reverse-logistics firms to collect used bags for chemical recycling into pyrolysis oil, thereby moving closer to a fully circular packaging economy.

Conclusion

In an era when sustainability credentials can make or break brand equity, JXD offers more than compliant packaging—it delivers a strategic platform for growth. Its 15-year track record, fortified by world-class certifications, patented technologies, and a customer-first ethos, positions JXD not merely as a supplier but as an innovation ally. For apparel brands determined to dress the world responsibly, JXD’s clothes packaging bags are the first—and most visible—step on that journey.