In daily life and industrial production, plastic bags are commonly used packaging materials. However, with the increasing awareness of environmental protection, biodegradable bags have gradually entered the public eye. These two types of bags exhibit significant differences in multiple aspects, which profoundly impact the environment and consumer choices.

一、Material Introduction

The core raw materials of ordinary plastic bags are petroleum-based polymer compounds such as polyethylene and polypropylene. These raw materials are derived from non-renewable petroleum resources, with stable molecular structures that make them difficult to decompose in the natural environment. In contrast, biodegradable bags use more environmentally friendly materials, mostly renewable biomass such as starch, cellulose, and polylactic acid (PLA). Some of them also incorporate degradable polymer materials, which can be decomposed by microorganisms in specific environments.

二、Processing Technology

The processing process of ordinary plastic bags is mature and simple, usually involving steps such as raw material melting, extrusion blow molding, and cooling forming. It has low requirements for equipment, high production efficiency, and is suitable for large-scale mass production. Due to the characteristics of their raw materials, biodegradable bags have a more complex processing technology. They require precise control of parameters such as temperature and pressure, and some even need special modification treatment to improve performance. This means higher requirements for production equipment and technology, and a relatively longer production cycle.

三、Market Application Fields

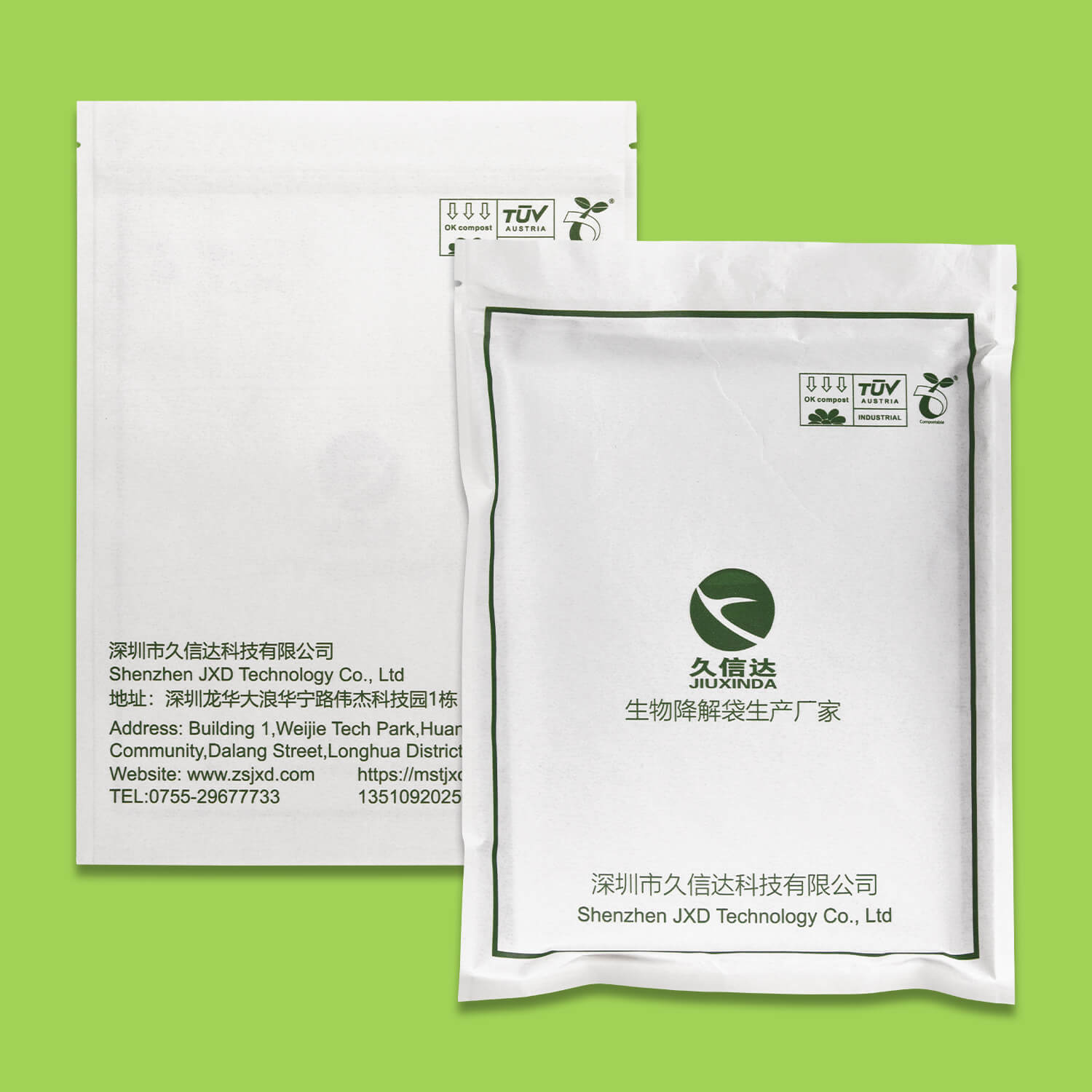

Relying on the advantages of low cost, good sealing, and excellent ductility, ordinary plastic bags are widely used in fields such as supermarket shopping, food outer packaging, and industrial product protection. They dominate in scenarios with low environmental protection requirements. Biodegradable bags, on the other hand, are mostly used in scenarios with strict environmental protection requirements. These include packaging for disposable tableware in the catering industry, mulch films in the agricultural field, packaging for some disposable products in the medical industry, and product packaging of enterprises that value their environmental image.

四、Price

Due to the easy availability of raw materials and low processing costs, ordinary plastic bags are affordable. For example, the unit price of common supermarket shopping bags is usually a few cents to a few dimes. Biodegradable bags, however, are more expensive due to high raw material costs and complex processing technology. Their price is generally 2 to 5 times that of ordinary plastic bags, which limits their popularization to a certain extent.

五、Environmental Performance

Environmental friendliness is the fundamental difference between biodegradable bags and ordinary plastic bags. Ordinary plastic bags are difficult to decompose and cause “white pollution”, while biodegradable bags can decompose in the natural environment and have little impact on the environment. The decomposition cycle of ordinary plastic bags in the natural environment is as long as 200 to 1000 years. Their massive use leads to “white pollution”, which contaminates soil and water sources and endangers the survival of animals and plants. Under suitable conditions of temperature, humidity, and microorganisms, biodegradable bags can be completely decomposed into carbon dioxide, water, and organic matter within 6 to 12 months. They do not cause long-term environmental pollution, and can also reduce reliance on petroleum resources, conforming to the concept of sustainable development.

Overall, although biodegradable bags have disadvantages in terms of price and processing technology, they have significant advantages in environmental protection and sustainable use of resources. With the advancement of technology and the promotion of environmental protection policies, they are expected to gradually replace ordinary plastic bags and become the mainstream choice in the packaging field in the future.