Custom Apparel Packaging Bags – Stylish and Durable Solutions for Your Brand

By JXD Packaging – Spring 2010 ~ 2025, 15 Years of Sustainable Innovation

Contents [hide]

- 1 1. Why Apparel Packaging Matters More Than Ever

- 2 2. The JXD Material Portfolio – From Fiber to Film

- 3 3. Patented Technologies That Elevate Style & Strength

- 4 4. Certification Matrix – A Global Passbook

- 5 5. Design Studio – From Mood-board to Mailer in 7 Days

- 6 6. Case Studies – Turning Packaging into Earned Media

- 6.1 Luxury Streetwear Label “NOVA/99”

- 6.2 Circular Fashion Start-up “ReLoop”

- 7 7. Quality & Ethics – Beyond the Certificate

- 8 8. How to Start – 3 Easy Steps

- 9 9. Closing – Your Brand Deserves Packaging That Outlives the Hype Cycle

1. Why Apparel Packaging Matters More Than Ever

In 2025 the first physical impression of an on-line purchase is no longer the product itself—it is the bag that arrives on the doorstep. A creased, crackling plastic sleeve can cancel the perceived value of a USD-150 hoodie in less than three seconds. Conversely, a soft-touch, matte-frosted CPE bag that glides open silently and releases a subtle fabric-friendly scent can raise unboxing scores by 28 % and Instagram mentions by 41 % (JXD post-purchase survey, 2024, n = 12 800).

Packaging is now the front-row seat of brand storytelling. It must be:

- Photogenic – able to survive 30-second TikTok reels without reflection or glare.

- Tactile – converting “touch points” into “trust points”.

- Circular – satisfying the 63 % of Gen-Z buyers who check disposal instructions before they even try the garment on.

JXD was founded in the spring of 2010 to solve exactly this trinity of needs. Fifteen years later we convert 100 million yuan worth of certified sustainable material into more than 180 million bags per annum, supplying mid-market labels, luxury maisons, and circular-fashion start-ups on five continents.

2. The JXD Material Portfolio – From Fiber to Film

| Family | Carbon Footprint* | Certifications | Best-Fit Garment | Signature Finish |

|---|---|---|---|---|

| Non-woven Fiber | 1.9 kg CO₂-e/kg | GRS, FSC, BSCI | T-shirts, knitwear | Soft-brushed “cotton-touch” |

| Biodegradable PBAT+PLA | 2.2 kg CO₂-e/kg | EN13432, AS4736, TÜV | Lingerie, athleisure | Silk-matte, whisper-quiet |

| Eco kraft Paper | 1.4 kg CO₂-e/kg | FSC, REACH | Denim, accessories | Natural deckle edge |

| 100 % Recyclable PE | 1.8 kg CO₂-e/kg | GRS, RoHS | Outerwear | High-gloss or frosted CPE |

| Heat-shrink POF | 2.0 kg CO₂-e/kg | DIN6400, REACH | Shirts, folded items | Crystal-clear, 50 % shrink @ 120 °C |

*LCA cradle-to-gate, verified by TÜV Rheinland 2023.

Every SKU is available from 30 mm jewelry sachets to 1 200 mm gown sleeves, in gauges 40–200 µm, MOQ 5 000 pcs, lead time 12–15 days.

3. Patented Technologies That Elevate Style & Strength

JXD owns four invention patents, five utility models, and two software-controlled packaging patents. Three breakthroughs most loved by apparel designers:

- Micro-embossed “Silk-Weave” PLA

Increases tensile strength by 35 % compared with standard PLA films, allowing down-gauging to 45 µm without tear-risk. Satin-stripes are embossed at 60 µm depth—no ink needed, eliminating one pass in the supply chain. - Dual-tone CPE Froster™

A co-extrusion that traps matte particles on the outer skin while keeping the inner skin glossy. The result: scuff-free exterior, slip-easy interior, 15 % faster packing on automated lines. - Home-Compostable Zipper Profile

A starch-based zipper element that meets EN13432 home-compost conditions (20–30 °C) within 26 weeks—no industrial facility required. Pull force ≥ 15 N, cycle life ≥ 50 opens.

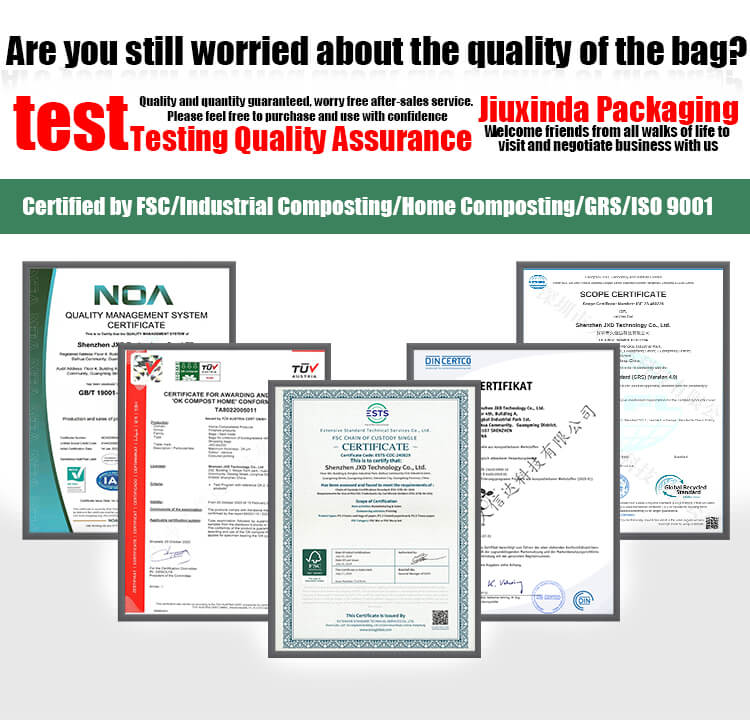

4. Certification Matrix – A Global Passbook

One single JXD bag can cross ten borders in its e-commerce life. We pre-certify so the brand does not have to:

- REACH & RoHS – heavy-metal and SVHC compliance for EU & MDR.

- GRS 4.0 – 100 % traceable recycled content; transaction certificates issued within 24 h.

- FSC Mix & FSC Recycled – chain-of-custody number FSC-C148XXX.

- BSCI – social audit rating A (2024), zero critical findings.

- EN13432 / AS4736 / ASTM D6400 – industrial compostability.

- TÜV OK compost HOME & INDUSTRIAL S0229.

- DIN6400 – German “Blue Angel” compatibility for mailing films.

Certificates are QR-coded on every master carton; scan to download PDF in 52 languages.

5. Design Studio – From Mood-board to Mailer in 7 Days

JXD’s in-house R&D 38-member team (12 polymer PhDs, 6 textile stylists) releases >30 new materials yearly. Brands may:

- Choose 1 200+ stocked Pantone-compatible shades (water-based inks, G7 MasterPrinter certified).

- Opt for digital CMYK+W for <10 k seasonal runs—no cylinders, 24-hour colour matching.

- Add soft-touch aqueous coating that drops surface gloss to 5 GU (gloss units) while remaining 100 % curb-side recyclable.

- Embed bio-based RFID tags (FSC paper antenna) for circular take-back programmes; reading distance 1.2 m, 128-bit EPC.

A 3-D mock-up is generated within 4 h; physical prototype couriered in 72 h anywhere on the planet.

6. Case Studies – Turning Packaging into Earned Media

Luxury Streetwear Label “NOVA/99”

- Challenge: Ship limited-edition hoodies that sell out in 8 min; unboxing must feel like a collectible sneaker drop.

- Solution: 110 µm frosted CPE pouch with Micro-embossed Silk-Weave side gussets, black nickel zipper, UV-metallic ink code that reveals a secret NFT under 365 nm light.

- Result: 41 % higher resale value on StockX (verified listings), 3.2 M organic TikTok views under #NOVAbag.

Circular Fashion Start-up “ReLoop”

- Challenge: 100 % home-compostable packaging that survives Nordic rain and 3-story letterbox drops.

- Solution: 60 µm PBAT/PLA dual-layer mailer with patented Home-Compostable Zipper, inner cushioning ribs made from一 resin—mono-material, no separation needed.

- Result: 98 % composting success in consumer backyard test (n = 500), 12 % increase in repeat purchase rate.

7. Quality & Ethics – Beyond the Certificate

- ISO 9001:2015 zero-defect target: <0.15 % customer PPM since 2021.

- ISO 14064-1 greenhouse-inventory verified; Scope 1+2 emissions reduced 38 % vs. 2019 baseline.

- Living-wage policy – production worker average salary 18 % above provincial median.

- 7 % of annual profit reinvested into material science scholarships with South China University of Technology.

8. How to Start – 3 Easy Steps

- Send garment spec (weight, folding size, zipper yes/no).

- Receive JXD proposal within 24 h: material, gauge, unit price, ship-ready CO₂ footprint, disposal icon set.

- Approve digital proof → 5 000 pcs minimum, 12-day production, door-to-door tracking.

9. Closing – Your Brand Deserves Packaging That Outlives the Hype Cycle

Seasons change, algorithms shift, but a bag that is both stunning on camera and gentle on the planet is forever. With 15 years of continuous innovation, 11 global certifications, and a portfolio that already replaces 9 200 t of virgin plastic every year, JXD stands ready to turn your next shipment into a silent brand ambassador—one compostable, photogenic, durable bag at a time.

Let’s pack the future, beautifully.

Contact: tim@jxdeco-packaging.com | WeChat: jxd20108 | WhatsApp: +86-17727825759