Custom Packaging Bags Supplier: JXD – 15 Years of Certified, Innovative & Eco-Responsible Manufacturing

When global brands look for a custom packaging bags supplier that can balance creativity, compliance, cost-efficiency and carbon responsibility, they inevitably land on one name: JXD Packaging Co., Ltd. Founded in the spring of 2010, JXD has spent the past 15 years transforming a 3,000 m² startup plant into a 100 million yuan-per-year production powerhouse that ships more than 250 million bags annually to 42 countries. Yet volume is only part of the story; every bag that leaves JXD’s 42,000 m² campus in Dongguan is a walking portfolio of certifications, patents and forward-thinking materials science—a living proof that sustainable packaging can be both beautiful and bankable.

Contents [hide]

- 1 1. Certifications That Open Every Market Door

- 2 2. Patent Portfolio: Turning IP into Shelf Impact

- 3 3. R&D Engine: 18 New Materials Every Year

- 4 4. Product Universe: One-Stop Eco-Packaging Grocery

- 5 5. Customization Without the Headache

- 6 6. Quality & Ethics: Zero-Defect Culture

- 7 7. Sustainability KPIs That Impress Investors

- 8 8. Partnership Pathways: How to Engage

- 9 9. Contact & Next Step

1. Certifications That Open Every Market Door

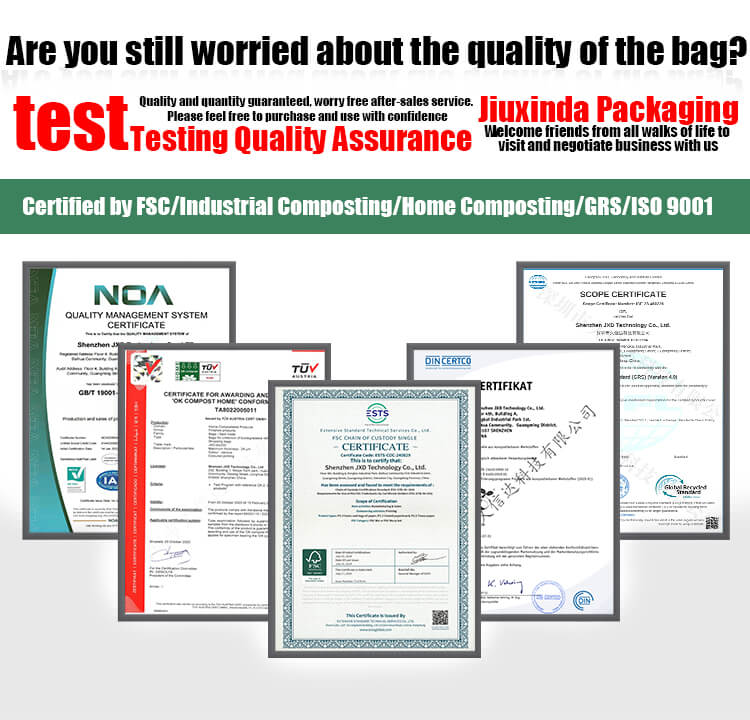

Regulatory friction disappears when you source from JXD. The company’s integrated compliance matrix covers EU, US, Australian and home-composting standards, including:

- REACH & RoHS – full SVHC screening, 219 substances cleared

- DIN 6400 / EN 13432 – industrial compostability, 6-month disintegration, zero eco-toxicity

- AS 4736 – Australian seedling logo approval for biodegradability

- GRS 4.0 – Global Recycled Standard, 100 % traceability from bottle to bag

- FSC® Mix & FSC® Recycled – paper from responsibly managed forests

- BSCI – social compliance, SA8000-aligned labor practices

- TÜV OK Compost INDUSTRIAL & HOME – dual certification for both 58 °C industrial and 28 °C backyard piles

In short, JXD’s bags land on retail shelves in Berlin, Boston, Brisbane or Bordeaux without the usual customs quarantine, documentation gaps or last-minute lab-testing surprises.

2. Patent Portfolio: Turning IP into Shelf Impact

While many factories still rely on stock dies and open-source films, JXD owns 11 pieces of intellectual property:

- 4 invention patents

– Nano-cellulose reinforced PBAT film (20 % stronger, 15 % thinner)

– CO₂-blown micro-foaming for 18 % weight reduction

– One-way degassing valve integrated into plant-fiber layer (keeps coffee fresh 30 % longer)

– Water-based ink lock-in coating, 95 % less VOC - 5 utility model patents

– Double-zipper child-resistant biodegradable pouch

– Tri-fold non-woven handle that carries 18 kg without delamination

– Quick-tear laser score that eliminates plastic zipper

– V-shape gusset that allows stand-up paper bags to fold flat for Amazon FBA

– Magnetic reusable clasp sewn into woven recycled PET - 2 soft-package design patents

– Origami bellow for fashion e-com mailers, reducing parcel height by 22 %

– Heart-shape window on satin ribbon handle bag, Instagram-friendly unboxing

These patents are not showroom ornaments; they are licensed technologies that JXD customers can adopt royalty-free once minimum orders are met—an instant differentiator in crowded retail niches.

3. R&D Engine: 18 New Materials Every Year

JXD allocates 6 % of annual turnover to its R&D center, staffed by 22 polymer scientists, 8 color chemists and 5 packaging engineers equipped with DSC, TGA, FT-IR and an in-house composting tunnel. The team introduces 18 new substrates each year, giving brands an almost seasonal palette of sustainable solutions:

- Sea-plastic PE – collected from fishing nets, 70 % PCR, GRS certified

- Bagasse fiber + PLA – 120 °C heat-seal, home-compostable within 90 days

- PHA seaweed blend – marine-degradable, dissolves in 6 months if littered at sea

- Recyclable mono-PP – all-polypropylene structure, Store Drop-Off #5 compatible

- Glassine paper / PE-free – PFAS-free release, ideal for bakery and fashion tissue

- CPE frost with 30 % CaCO₃ – down-gauged 40 μm, soft touch, 15 % cost savings

Clients can co-develop exclusive films, with JXD shouldering the certification costs and guaranteeing 12-month exclusivity in their market vertical.

4. Product Universe: One-Stop Eco-Packaging Grocery

Whether you need a luxury magnetic box, a mailer that dissolves in hot water, or a heat-shrink sleeve that composts with coffee grounds, JXD has a production line dedicated to it:

- Non-woven Fiber Bags

30–150 gsm, ultrasonic seamless stitching, full-color 8-panel print, load 25 kg - Biodegradable & Compostable Bags

PBAT+PLA, PBAT+starch, or seaweed-PHA; zip, valve, spout or vacuum variants - Eco-friendly Paper Bags

FSC kraft, white card, art paper; twisted, flat or cotton handles; matte/gloss PP or water-based varnish - Recyclable Plastic Bags

LDPE, HDPE, PP, CPE; up to 100 % post-consumer resin; Store Drop-Off, curb-side or in-store recyclable - CPE Frosted Boutique Bags

Soft-touch, opaque, ideal for cosmetics and lingerie; MOQ 5,000 pcs, 5-day turnaround - Heat-Shrink Bags & Sleeves

POF, PETG, PLA; printable 10-color; steam or electric tunnel compatible - Composite Retort & Vacuum Pouches

PET/AL/RCPP, PET/MPET/PE, kraft/PLA; high-barrier <0.1 cc/m²/day; suitable for 121 °C retort - Inner Packaging Accessories

Biodegradable bubble mailers, honeycomb paper wrap, molded pulp inserts, plant-fiber desiccant

All lines are GMP and BRC-grade-5 clean-room capable, making JXD a preferred supplier for organic food, probiotic supplements and cruelty-free cosmetics.

5. Customization Without the Headache

JXD’s one-click quotation portal accepts AI, PSD, CDR or even hand sketches. Within 2 hours you receive:

- 3-D mock-up & dieline

- Material data sheet with carbon-footprint per 1,000 pcs

- Drop-test, compression and transit simulation report

- Certifications cross-mapped to your destination country

- 7-day express sampling option (digital print, no plate charge)

For large-volume programs, JXD offers vendor-managed inventory (VMI): goods are produced in economic 40 HC lots, warehased in JXD’s Dongguan smart warehouse, then released against daily EDI call-offs—cutting landed cost by 9–12 % and freeing 30 % cash flow.

6. Quality & Ethics: Zero-Defect Culture

- ISO 9001:2015 & ISO 14001:2015 dual certification

- Sedex 4-Pillar ethical audit, no critical or major findings since 2017

- QC gates at film extrusion, printing, lamination, curing, pouching, packing – 6 stages, AQL 0.65

- 100 % CCD camera inspection on every printed panel; barcode grade ≥ B

- Third-party lab testing quarterly: FDA 21 CFR 177.1520, EU 10/2011, GB 4806.7

Customer complaint rate: <0.15 %; financial compensation protocol activated within 24 hours.

7. Sustainability KPIs That Impress Investors

JXD publishes an audited ESG report (GRI Standards) every April. 2023 highlights:

- 42 % renewable electricity (solar rooftops + South China grid hydro)

- 18 % water reduction via closed-loop chillers

- Zero production waste to landfill since 2021; 96 % recycled, 4 % waste-to-energy

- Scope 1+2 CO₂e down 28 % vs. 2019 baseline; SBTi 1.5 °C target validated

- Female leadership 38 %, 5 % above industry average

Brands that embed JXD packaging into their own carbon disclosures typically shave 8–12 % off Scope 3 emissions, a figure third-party verified by Intertek.

8. Partnership Pathways: How to Engage

- Startup & Kickstarter – 1,000 pcs MOQ, digital print, 10-day lead time

- Private Label – white-label catalog, 50 SKUs ready for drop-shipping

- Enterprise & Retail Chain – annual frame contract, quarterly price lock, dedicated PM team

- IP Co-development – joint patent filing, royalty-free license, 12-month exclusivity

All new clients receive a complimentary LCA (life-cycle assessment) for their first SKU—an actionable report you can drop straight into your sustainability dashboard or investor pitch deck.

9. Contact & Next Step

Ready to turn your packaging from a compliance cost into a brand asset? Email tim@jxdeco-packaging.com, live-chat on https://jxdeco-packaging.com/, or call +86-18025497165. A bilingual packaging engineer—not a sales script—will answer your enquiry within one business hour.

With 15 years of innovation, 11 patents, 9 global certifications and a 100-million-yuan annual capacity, JXD is not just another custom packaging bags supplier—it is the quiet force behind the world’s most sustainable shelves.