Introduction

In 2025, packaging is no longer a “nice-to-have”; it is the first physical touch-point between a digital-native brand and a human customer. For micro-enterprises and side-hustles that live on TikTok Shop, Etsy, farmer’s markets or Shopify Lite, a custom bag can outsell a 5 % discount code because it travels on subways, sits on kitchen counters and is photographed for Instagram Stories. Yet most founders still Google “how to get custom packaging bag for small business” only to drown in MOQs (minimum order quantities) of 10 000 pieces, FOB Shanghai jargon and freight quotes higher than the product itself. lists vetted suppliers that accept 5000-piece runs, and shows you how to move from idea to doorstep in 30 days without sacrificing margin or sustainability.

1. Start with Strategy, Not Photoshop

1.1 Define the Job of the Bag

- Is it primary packaging (touching food) or secondary (mailer)?

- Does it need one-way degassing for coffee, oxygen barrier for jerky, or child-resistance for pet treats?

- Will it be displayed on a peg-hook, a boutique shelf, or shipped in a polymailer?

Write down every regulatory and functional requirement before you open Canva; changing structure after artwork is finished costs USD 250–600 in new plates.

1.2 Reverse-Engineer Unit Economics

Target landed cost of packaging ≤ 8 % of retail price for commodity items, ≤ 15 % for premium gifts. If your granola retails at USD 6.99, your finished bag must land at ≤ USD 0.56 including freight and import duty. Use the live calculator at Pacdora.com to test 3-digit MOQs instantly.

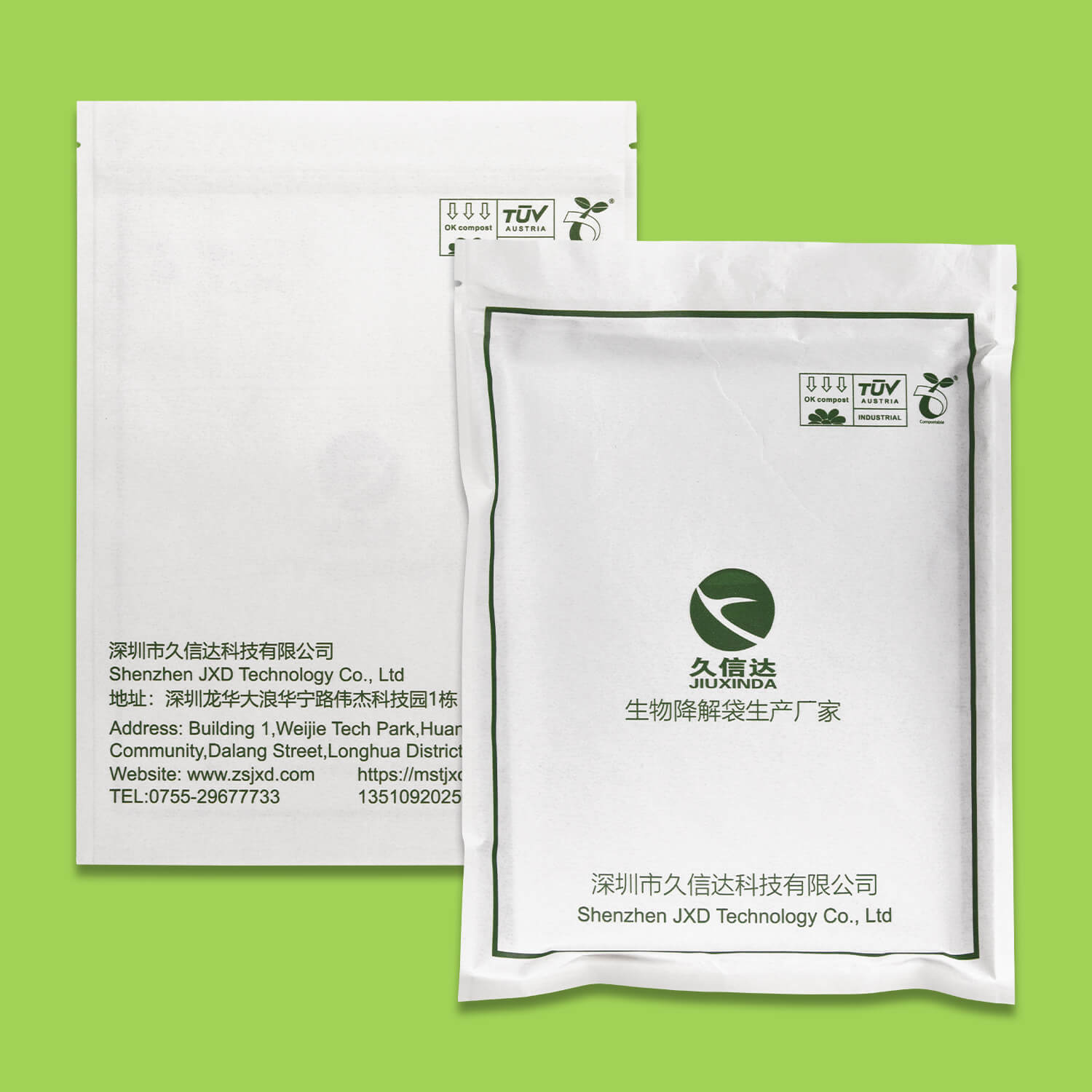

1.3 Sustainability Filter

48 % of Gen-Z consumers cancelled a brand in 2024 over “green-washing.” Decide early: recyclable PE-PE, compostable PLA, paper with water-based barrier, or multi-use zipper pouches. Each choice narrows the supplier universe and prevents re-work.

2. Pick the Right Bag Architecture

| Product Type | Recommended Structure | MOQ Sweet Spot | Supplier Example |

|---|---|---|---|

| Coffee, tea | Foil-lined stand-up + degassing valve | 500 | Colorful Packaging |

| Spice rubs | Kraft PET/AL/PE flat bottom | 1 000 | Jingsourcing |

| Cosmetics sachets | Matte PET/PE laser-scored | 300 | Zenpack |

| Apparel mailers | 100 % recycled LDPE mailer with 2-colour print | 250 | Noissue |

| Frozen pet food | Retort pouch 4-mil nylon | 2 000 | ABC Packaging Direct |

Tip: If you need < 300 pieces for a market-test, buy blank stock pouches from Amazon or Uline, print metallic labels on a Primera LX910 and heat-transfer—your prototype cost drops to USD 1.10 each.

3. Artwork that Converts

3.1 Mandatory Copy Checklist

- Front: brand name, weight, flavour hook.

- Back: nutrition panel, barcode, allergen statement, batch code area, social handle.

- Use Nielsen “five-second” rule: value proposition must be readable at 3 ft.

3.2 Free Tools that Export Print-Ready Dielines

- Canva Print: 19 bag styles, auto-bleed, 0.125” safe-zone guides .

- Pacdora 3-D: download AI dieline with zipper, tear-notch and hang-hole already vectored.

- Figma community file “Pouch-Mock-2025” keeps Pantone TCX colours accurate.

3.3 Colour Management

Convert RGB to Pantone 200 C (Coke red) or 349 C (Starbucks green) early; Chinese flexo printers charge USD 60 per spot colour change. Request ink-drawdown on the actual film substrate—paper proof lies.

4. Supplier Short-List for 2025 (All Verified < 5 000 MOQ)

| Region | Company | Speciality | MOQ | Ships to | Notes |

|---|---|---|---|---|---|

| USA | Zenpack | Structural design + sustainability | 500 | Global | 3-day prototype with Kongsberg table |

| USA | Hatteras | Folding cartons, flexo bags | 1 000 | NA | 40-year boutique printer, free warehousing 30 days |

| China | Colorful Packaging | Coffee valve pouches | 500 | DDP Amazon | 12-day ocean + inland to US warehouse |

| China | Jingsourcing | All bag types, bilingual PM | 300 | DDP EU/US | Can bundle with product sourcing |

| USA | Fast Custom Boxes | Mailers, frosted windows | 100 | NA | 5-day turnaround, free design |

5. Negotiation & Sampling Workflow

Day 1–2: Send RFQ pack

- PDF dieline, quantity tiers (500 / 1 000 / 2 000), target EXW or DDP price, required certifications (FDA, BRC, ASTM D6400).

- Ask for similar project photos + customer reference.

Day 3–5: Pre-Quote Screening

Reject any supplier that quotes without asking about barcode location or zipper type—they are brokers.

Day 6–10: Digital Prototype

Approve 3-D mockup; check:

- Hang-hole diameter ≥ 6 mm for US pegs.

- Zipper placement ≥ 15 mm below top seal to avoid heat-seal burn.

- Matte/gloss ratio—75 % matte with 25 % spot gloss increases perceived value 11 % in eye-tracking studies.

Day 11–20: Physical Golden Sample

Order 5–10 pieces. Run three tests:

- Drop test: 1.2 m on concrete, 6 faces, no seal rupture.

- Compression test: stack 5 cases, 24 h, ≤ 5 % deformation.

- Transit simulation: freeze/thaw −18 °C ↔ 40 °C, 3 cycles, no delamination.

Approve sample with signed “golden sample” card; attach to PO to avoid “production drift.”

6. Logistics & Cash-Flow Hacks

6.1 Incoterm Choice

- ≤ 300 kg: use DDP air courier (FedEx) to avoid customs surprises.

- 300–1 000 kg: LCL sea + UPS Ground last-mile; saves 32 % vs air.

- ≥ 1 000 kg: FOB Shenzhen + US customs bond; lead time 18 days but 55 % cheaper.

6.2 Tariff Classification

Pouches of < 20 % plastic by weight can enter under 4819.40 (paper bags) at 0 % duty vs 3923.29 (plastic) at 3.2 %—worth USD 400 per 10 000 bags.

6.3 Payment Terms

Use 30 % T/T deposit + 70 % against BL copy. Escrow via Alibaba Trade Assurance for first order; switch to 30-day OA (open account) after 3 successful runs to free cash.

7. Launch, Measure, Iterate

7.1 KPI Dashboard

- Damage rate target < 0.5 %

- Instagram mentions with package hashtag ≥ 5 % of orders

- Unboxing video conversion: 1 video per 50 shipped → 8 % lift in repeat purchase

7.2 Post-Purchase Survey

Ask two questions:

- “On a 1–10 scale, how likely are you to reuse this bag?”

- “What would you pay for a refill that comes in a plain compostable liner?”

Answers will tell you when to pivot to refill pouches and cut packaging cost 40 %.

8. 2025 Trend Watch

- Laser-Engraved QR for Limited Editions: xTool F1 engraves variable QR codes on kraft pouches at 1 000 mm/s—perfect for NFT loyalty drops .

- Mono-Material PE-PE with Water-Based Ink: curbside recyclable, no need to remove zipper; MOQ now 1 000 thanks to Huhtamaki’s small-batch extruder.

- 30 % Post-Consumer Recycled (PCR) Food-Grade Film: FDA-approved for direct food contact; premium of only USD 0.02 per pouch at 5 000 MOQ.

Conclusion

Custom packaging bags are no longer gated by 10 000-piece minimums or six-figure budgets. By mapping function to structure, using free cloud-based dieline tools, and choosing vetted suppliers that specialise in 500–2 000 piece runs, a five-person start-up can launch retail-ready pouches in under a month for less than the cost of a flagship iPhone. Treat the bag as the only salesperson that never sleeps—design it, test it, ship it, then let your customers finish the marketing for you.