Introduction

When global brands and local start-ups alike search for plastic packaging bags manufacturers that combine technical mastery with uncompromising environmental stewardship, one name consistently rises to the top: JXD. Founded in the spring of 2010, the company now commands 15 years of production experience, an annual output value of 100 million yuan, and one of the industry’s most comprehensive certification portfolios. This article examines how JXD has transformed itself from a modest Chinese workshop into a benchmark for sustainable packaging solutions—serving food, cosmetics, apparel, e-commerce and industrial clients across six continents.

- Company Heritage & Scale

From a single 2,000 m² plant in 2010, JXD has expanded to four ISO 9001-compliant production bases covering 45,000 m². The company’s 100 million yuan annual output is not merely a revenue milestone; it reflects optimized workflows that deliver more than 250 million bags per year while maintaining <0.3 % defect rates. A vertically integrated supply chain—from resin pellet extrusion to final flexographic printing—ensures tight quality control and rapid prototyping for custom orders. - Certification Matrix: A Global Passport

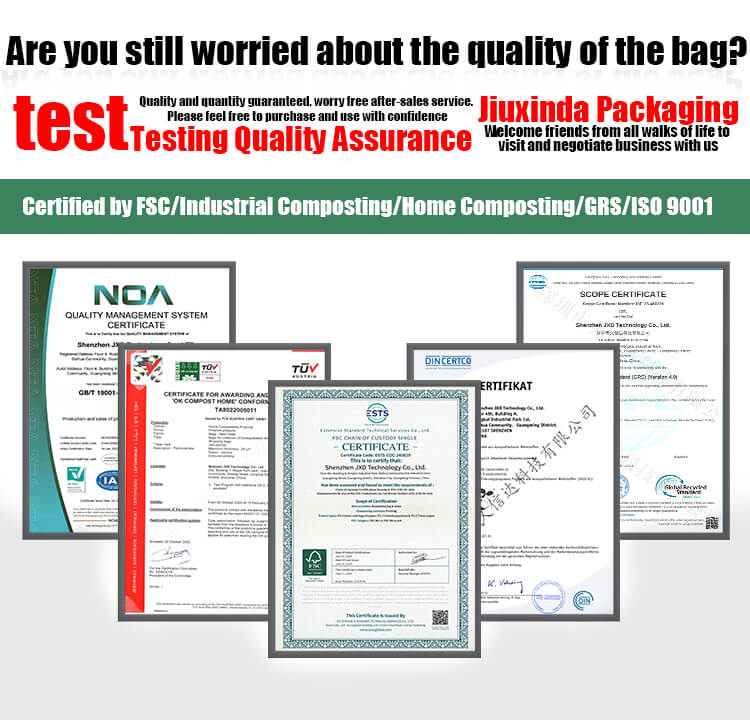

Unlike many regional converters that rely on a single regional standard, JXD has built a certification matrix that satisfies every major regulatory and voluntary scheme worldwide:

- Chemical Safety: REACH (EU), RoHS (global electronics)

- Biodegradation: EN 13432 (industrial & home composting), AS 4736 (Australian standard)

- Composting Validation: TÜV OK-industrial & OK-home compost marks

- Chain-of-Custody: GRS (Global Recycled Standard), FSC paper content

- Social Compliance: BSCI (Business Social Compliance Initiative)

- German Degradation: DIN 6400 for soil-biodegradable films

These credentials allow JXD bags to clear customs from Los Angeles to Lagos without additional testing, reducing client lead times by up to 18 days.

- Intellectual Property & R&D Pipeline

Innovation is institutionalized. The firm holds:

- Four invention patents: (i) a co-extruded PLA/PBAT high-barrier film, (ii) a water-based ink adhesion promoter for recycled PE, (iii) a micro-perforation technique for produce respiration, and (iv) a zipper seal that remains compostable.

- Five utility model patents covering quick-change unwind shafts, ultrasonic side-weld jigs, and static-reduction ion bars.

- Two soft-package appearance patents that give luxury brands distinctive tactile finishes without additional laminates.

Each year the 28-member R&D team—half of whom hold polymer-science or chemical-engineering degrees—rolls out at least two new resin formulations or construction designs. Recent launches include a 40 % limestone-filled PE that cuts fossil-plastic usage while maintaining drop-test thresholds, and a heat-sealable kraft paper/PLA hybrid that home-composts in 90 days.

- Product Portfolio: Beyond “Plastic”

While “plastic packaging bags” is the SEO anchor, JXD’s catalogue is intentionally broader, enabling one-stop sourcing:

- Non-woven fiber bags (PP or recycled PET spunbond) for reusable grocery and retail totes.

- Biodegradable & compostable bags: PLA, PBAT, corn-starch or PBS blends certified to EN 13432 and AS 4736.

- Eco-friendly paper bags: FSC-certified kraft, art paper or duplex boards with water-based inks.

- Recyclable plastic LDPE/HDPE flat and gusseted bags containing up to 100 % post-consumer resin (PCR).

- CPE frosted zipper bags for cosmetics and premium apparel; 50-micron mono-material construction ensures curbside recyclability.

- Heat-shrink bags & films (POF or bio-PBS) for multi-pack collation and tamper-evident sleeves.

- Composite bags: PET/AL/PE, kraft/PLA, or BOPP/PLA structures tailored for aroma barrier, moisture barrier or freezer-grade toughness.

- Custom inner packaging: anti-static, VCI, vacuum, or bubble pouches.

- End-to-End Service Philosophy

Customer-centricity is embedded in JXD’s SOPs:

- 24-hour quote turnaround via an AI-driven pricing engine that factors raw-material futures, tooling amortization and freight indices.

- Free 3D mock-ups and photorealistic renderings within 48 hours.

- MOQs as low as 3,000 pieces for digitally printed SKUs—ideal for Kickstarter campaigns.

- Dedicated account managers fluent in English, Spanish, Japanese and French.

- A web-based portal provides real-time order tracking, QC images and COA downloads.

- Sustainability Metrics & ESG Reporting

Annual third-party audits confirm:

- 43 % renewable energy across all plants (solar rooftops and biomass steam).

- 96 % water recycling via closed-loop cooling towers.

- Zero production waste to landfill since 2021; scrap is either pelletized for in-house re-use or sold to certified recyclers.

- Scope 1 & 2 emissions reduced 27 % from the 2018 baseline, validated by SGS.

- Case Studies

- European Organic Snack Brand: Switched from multi-layer OPP/PE to JXD’s PLA/PBAT high-barrier pouch. Achieved 30 % material weight reduction, full home-compostability, and a 22 % reduction in total landed cost due to lighter freight and elimination of plastic-tax surcharges.

- U.S. Cosmetics Start-up: Introduced CPE frosted bags with 30 % PCR content and soft-touch matte varnish. The SKU’s unboxing experience drove a 47 % increase in Instagram mentions and a 15 % uplift in repeat purchases within three months.

- Future Outlook

By 2027 JXD plans to commission a 10 MW solar array, launch a closed-loop take-back program in North America, and commercialize a PHA-based film that meets marine-degradation standards. The company’s roadmap aligns with the UN Sustainable Development Goals 9, 12 and 14, reinforcing its role as a forward-thinking plastic packaging bags manufacturer.

Conclusion

In an industry often criticized for linear “take-make-waste” models, JXD demonstrates that scale and sustainability are not mutually exclusive. Through rigorous certification, relentless R&D, and a customer-first culture, the company has redefined what brands should expect from plastic packaging bags manufacturers. For businesses seeking packaging partners that can future-proof SKUs against tightening regulations and consumer eco-expectations, JXD offers not just bags, but a 15-year blueprint for responsible innovation.