Packaging Bags Custom Manufacturer

When brand owners, retailers, and e-commerce platforms look for a packaging bags custom manufacturer, they are no longer satisfied with “cheap and fast.” Today’s brief must tick four simultaneous boxes: environmental compliance, design flexibility, reliable volume, and transparent ethics. Founded in the spring of 2010, JXD Packaging Co., Ltd. has spent the past 15 years proving that a Chinese manufacturer can deliver on all four—while scaling to an annual output value of RMB 100 million and earning the trust of Fortune 500 companies, niche start-ups, and government tenders across five continents.

Contents

- 1 From Local Workshop to Global Eco-Factory

- 2 Certifications That Open Every Market

- 3 Patent Pipeline: Turning R&D into Competitive Moats

- 4 Material Road-Map: What “Eco-Friendly” Actually Means

- 5 Product Portfolio: One-Stop Custom Shop

- 6 Customization Workflow: From Sketch to Shelf in 6 Weeks

- 7 Sustainability Beyond the Bag

- 8 Industries Served

- 9 Minimum Order Quantities & Lead-Times

- 10 Pricing Philosophy: Total Cost of Ownership

- 11 How to Start Your Custom Project Today

- 12 Final Word

From Local Workshop to Global Eco-Factory

JXD began as a 12-person pilot line in Dongguan’s Qingxi district. Fifteen years on, it has consolidated all production into a single, purpose-built 38 000 m² campus in Shenzhen’s Guangming District. Here, 380 employees run 18 extrusion–conversion lines 24/7, turning out more than 1 200 metric tons of finished bags—about 80 million pieces—every month. Each roll, sheet, and pouch is still extruded from lab-approved resins and tracked under integrated ISO 9001, ISO 14001, and ISO 45001 management systems.

Certifications That Open Every Market

Sustainability claims are only as strong as the third-party paperwork behind them. JXD’s quality-assurance vault contains original certificates and test reports for:

- REACH & RoHS – EU chemical safety and hazardous-substance limits

- DIN CERTCO & EN 13432 – industrial compostability for the EU market

- AS 4736 – Australian compostability standard (home-grown microbes)

- EN 13432 “OK Home Compost” – backyard composting at ≤ 30 °C

- GRS (Global Recycled Standard) v4.0 – 100 % traceable post-consumer PET bottle-to-bag solutions

- FSC™ Chain-of-Custody – paper from responsibly managed forests

- BSCI (amfori) – social compliance audits covering workers’ rights, health & safety, and fair remuneration

- TÜV Austria “OK Compost Industrial” – 6-month disintegration in 58 °C aerobic conditions

The above portfolio allows JXD bags to clear customs in 42 countries without additional testing—saving customers an average of 18 days lead-time and USD 2 400 per shipment in redundant laboratory fees.

Patent Pipeline: Turning R&D into Competitive Moats

Intellectual property is rarely associated with “commodity” packaging, yet JXD owns:

- Four invention patents (China National IP Administration):

- A PLA–PBS alloy with accelerated marine biodegradation

- A calcium-carbonate-filled PE that reduces polymer usage 38 % while maintaining 12 µm puncture strength

- A mono-material PP zipper that welds to both PET and PE films, enabling 100 % recyclable pouches

- A water-based barrier coating that replaces 1.5 mil EVOH for coffee valves

- Five utility model patents for ultrasonic folding, easy-tear perforations, and resealable child-proof sliders.

- Two software copyrights for online bag-cost calculators and carbon-footprint dashboards integrated into the customer portal.

Each patent is practiced in live SKUs, not shelf ornaments—generating 27 % of 2023 revenue.

Material Road-Map: What “Eco-Friendly” Actually Means

Customers often arrive asking for “the most sustainable bag.” JXD’s R&D team replies with a decision tree that balances functional barrier requirements, end-of-life infrastructure, and budget. The matrix below is updated every January after the annual materials summit with resin suppliers such as BASF, TotalEnergies Corbion, and Braskem.

| Grade | Polymer Base | % Bio or Recycled | Barrier (OTR) | End-of-Life | Typical Use |

|---|---|---|---|---|---|

| JX-PLA80 | PLA + PBAT | 80 % bio | 1800 cc/m²/day | Industrial compost | Produce, bakery windows |

| JX-MD30 | PE + CaCO₃ | 30 % mineral | 2100 cc/m²/day | Recycle #4 | Apparel mailers |

| JX-rPET50 | PET bottle flake | 50 % PCR | 12 cc/m²/day | Recycle #1 | Coffee, granola |

| JX-HDPEmono | m-PE | 0 %, but 25 % down-gauged | 1800 cc/m²/day | Recycle #2 | Ice bags, T-shirt sacks |

| JX-NK50 | PBS + starch | 50 % bio | 900 cc/m²/day | Home compost | Pet-waste bags |

| JX-FSCKraft | FSC paper + WBBC* | 0 % plastic | 3 cc/m²/day | Paper stream | Luxury boutique bags |

*Water-based barrier coating

All grades can be converted into the nine flagship constructions described below.

Product Portfolio: One-Stop Custom Shop

- Non-woven Fiber Bags (70–150 gsm)

Ultrasonic sewn for 15 kg load, dye-sublimation print 8-color photorealistic, optional Velcro or snap button. MOQ 1 000 pcs, 15-day delivery.

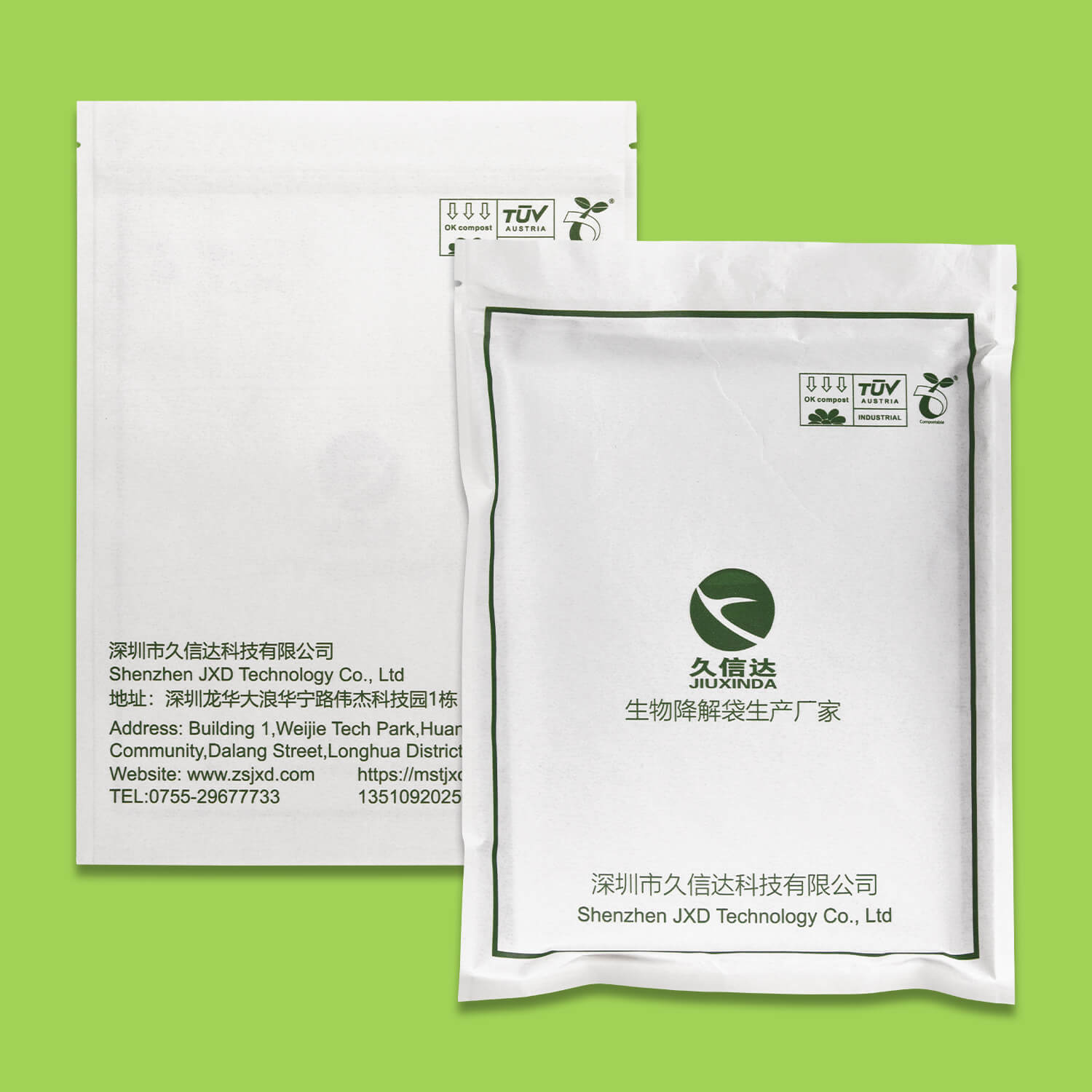

- Biodegradable & Compostable Bags

Flat, gusseted, or die-cut handles; from 15 µm to 180 µm; compliant with EN 13432/AS 4736. Available in clear, frosted, or tinted PLA.

- Eco-friendly Paper Bags

FSC-certified kraft, white-card, or art-paper; twisted, flat, or cotton rope handles; matte/gloss lamination or uncoated for easier recycling. Run lengths 500–500 000.

- Recyclable Plastic Mailers

Mono-material PE or PP with 50 % post-consumer resin; double-seal security strip; 3-side weld or bottom-gusset; custom 8-color flexo.

- CPE Frosted Zipper Pouches

Cast polyethylene for soft-touch “frost” finish; ideal for cosmetics, lingerie, electronics. Zipper and slider both recyclable #4.

- Heat-Shrink Film & Sleeves

PVC-free PETG, OPS, or PLA; shrink ratio 60–75 %; perforation, easy-tear, and tamper-evident T-seals. Suitable for full-body bottle decoration. - Composite Retort & Vacuum Pouches

2-ply (PET/AL/PE) or 3-ply high-barrier for ambient shelf life 24 months; optional microwaveable PP retort at 121 °C. Rotogravure print ≤ 10 colors. - Vacuum Compression Storage Bags

PA/PE co-extrusion; double-zip turbo valve; holds 80 % volume reduction for blankets and apparel. Custom size from 50 × 70 cm to 130 × 100 cm. - Specialty Inner Packaging

Anti-static IC tubes, conductive PE foam pouches, VCI rust-proof bags, and medical Tyvek® headers for sterilized devices.

Customization Workflow: From Sketch to Shelf in 6 Weeks

- Inquiry & Brief Review

A cross-functional team (sales engineer, CSR, compliance officer) reviews artwork, SKU list, and target market within 24 h. - Material Selection & LCA Snapshot

Customers receive a cradle-to-gate carbon report generated via the in-house SimaPro® engine, including disposal scenario modeling. - Prototype & Validation

Digital samples (EPSON SureColor) for color approval; laser cutter produces 10–50 hand samples in 48 h; functional tests (drop, vibration, compression) follow ASTM & ISTA-6. - Cylinder & Tooling

In-house engraving of rotogravure cylinders (Ø 400 mm max) or flexo plates (CDI 4835). Average cost USD 90–120 per color, amortized over 50 000 m². - Mass Production & On-line QA

100 % vision-inspection (BST TubeScan) for print defects; melt-index and seal-strength logged every 2 h; CpK ≥ 1.67 for critical dimensions. - Logistics & After-Sales

FOB Shenzhen, CIF Amazon ONT8, or DDP EU via JXD’s bonded warehouse in Rotterdam. ERP portal gives real-time OTS (order-tracking status) and generates COA, COO, and MSDS automatically.

Sustainability Beyond the Bag

- Solar Roof Initiative – 1.2 MW photovoltaic array covers 35 % of Dongguan plant electricity; saves 1 100 t CO₂e annually.

- Closed-loop Water Ring – Chilled water for blown-film lines is recycled through a 5-stage filtration tank; zero liquid discharge since 2021.

- Employee Green Fund – USD 0.005 per bag produced is contributed to local reforestation; 63 000 trees planted to date.

- Take-back Pilot – EU retail partners mail used JXD mailers to a partner recycler; pellets are returned to JXD’s blown-film line at 25 % inclusion rate.

Industries Served

- Fashion & Apparel – Zara, H&M, C&A, Decathlon

- Food & Beverage – Nestlé coffee pods, KraftHeinz grated cheese, Yum! Brands delivery bags

- Health & Beauty – L’Oréal, Estée Lauder, Sephora Collection

- E-commerce & 3PL – Amazon SIOC-compliant mailers, Shopify merchants, Cainiao Network

- Electronics & Industrial – Lenovo tablet sleeves, DJI drone pouches, Bosch power-tool bags

Minimum Order Quantities & Lead-Times

| Process | MOQ (pcs) | Cylinder Cost | Lead-Time |

|---|---|---|---|

| Flexo (surface print) | 3 000 | USD 60/color | 12 days |

| Gravure (high-speed) | 30 000 | USD 110/color | 18 days |

| Digital (no cylinders) | 500 | None | 7 days |

- Expedited 72-hour service available for digital and stock sizes.

Pricing Philosophy: Total Cost of Ownership

JXD quotes “landed cost per 1 000 bags” including resin, ink, labor, duty, and predicted carbon offset. Customers routinely find that paying 8 % more for a compostable mailer eliminates 5 cents per parcel in EU Extended Producer Responsibility (EPR) fees—yielding a net saving.

How to Start Your Custom Project Today

- Email tim@jxdeco-packaging.com with artwork PDF, target volume, and destination country.

- Receive a 48-hour detailed quotation including resin grade, certification list, and shipping schedule.

- Approve digital proof; pay 30 % deposit; production begins; balance due against scanned B/L.

Final Word

In an industry awash with green-washing, JXD Packaging has built a 15-year track record of measurable compliance, verifiable patents, and repeat-buy customers in 62 countries. Whether you need 5 000 compostable boutique bags or 50 million recyclable e-commerce mailers, JXD delivers consistent quality, documented sustainability, and a customer-first mindset that turns packaging from a cost line into a brand asset.