In an era where environmental sustainability has become a critical global priority, compostable bags have emerged as a promising alternative to traditional plastic bags. These innovative products represent a significant advancement in sustainable packaging technology, offering consumers and businesses an environmentally responsible option for waste management. But what exactly constitutes a compostable bag, and how does it differ from other supposedly eco-friendly alternatives?

Contents

- 1 Understanding Compostable Bags: A Definition

- 2 The Science Behind Compostable Bags

- 3 Certification Standards and Quality Assurance

- 4 Industrial vs. Home Compostable Bags

- 5 Applications and Practical Uses

- 6 Environmental Impact and Considerations

- 7 The Future of Compostable Bags

Understanding Compostable Bags: A Definition

A compostable bag is a specially engineered container designed to completely decompose into natural elements under specific composting conditions, leaving no toxic residue or harmful microplastics behind. Unlike conventional plastic bags that can persist in the environment for hundreds of years, compostable bags are manufactured from organic, plant-based materials such as corn starch, potato starch, sugarcane fiber, or polylactic acid (PLA), which microorganisms can break down into water, carbon dioxide, and nutrient-rich biomass.

The fundamental distinction between compostable bags and other alternatives lies in their complete biodegradation process. While traditional plastics merely fragment into smaller pieces that persist as microplastics, compostable bags undergo complete molecular breakdown, transforming into beneficial compost that can enrich soil quality. This process typically occurs within 90 to 180 days under appropriate composting conditions, though the exact timeframe depends on the specific materials used and environmental factors.

The Science Behind Compostable Bags

Compostable bags are manufactured using various bio-based polymers that mimic the functionality of conventional plastics while maintaining environmental compatibility. The most common materials include:

Polylactic Acid (PLA): Derived from fermented plant starch, usually corn, PLA is one of the most widely used materials in compostable bag production. This thermoplastic polyester offers excellent strength and flexibility while remaining fully compostable under industrial conditions.

Starch Blends: These formulations combine natural starches from corn, potatoes, or tapioca with biodegradable polymers to enhance durability and reduce production costs. The starch component provides the primary biodegradable element, while additional polymers improve mechanical properties.

Polyhydroxyalkanoates (PHA): Produced through microbial fermentation of sugars, PHAs represent a family of naturally occurring biopolyesters that offer excellent biodegradability in various environments, including marine conditions.

Cellulose-based Materials: Derived from wood pulp or other plant fibers, these materials provide an excellent barrier to oxygen and moisture while remaining fully compostable.

Certification Standards and Quality Assurance

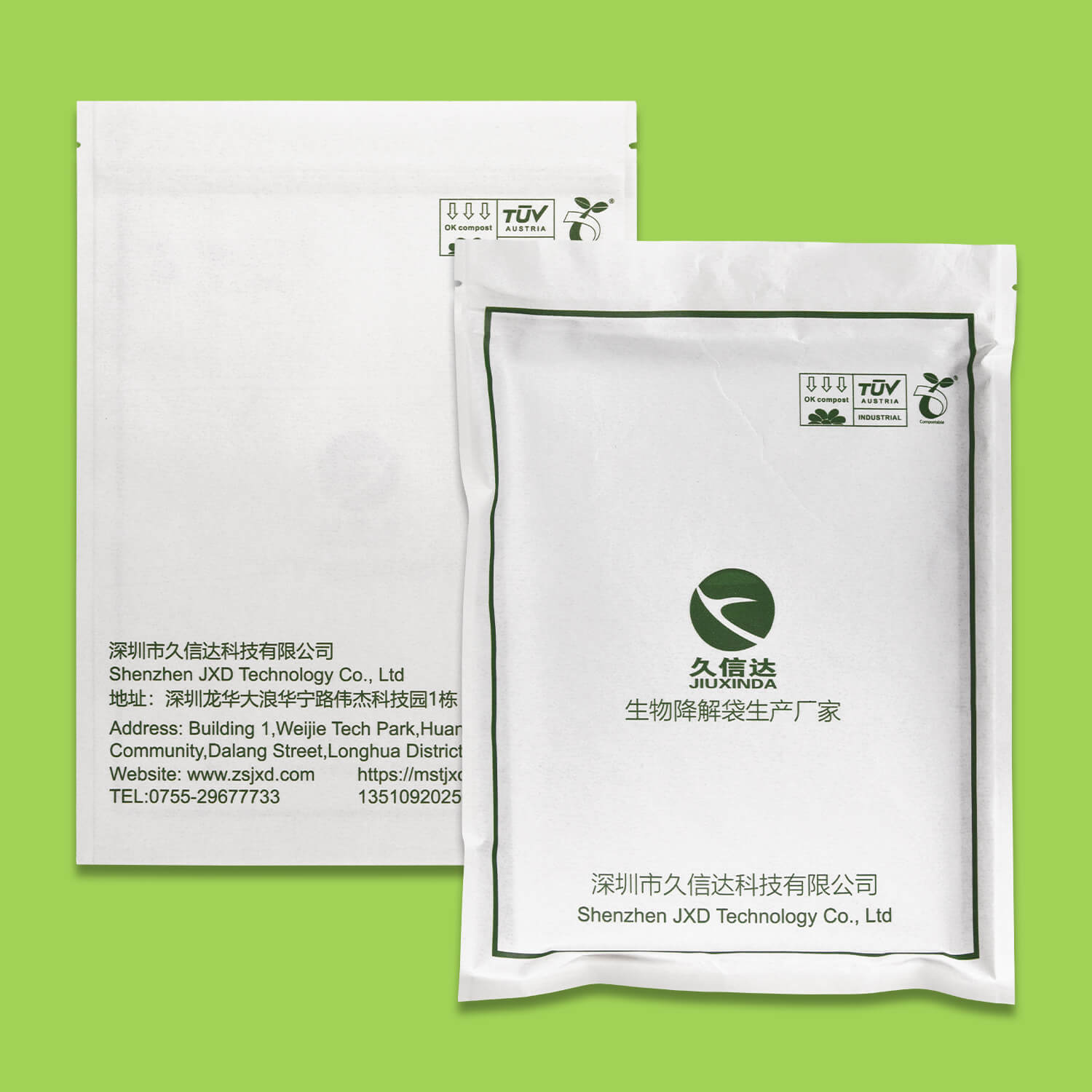

To ensure the integrity and environmental claims of compostable bags, various international standards and certification bodies have established rigorous testing protocols. The most recognized standards include:

ASTM D6400: The American Society for Testing and Materials standard specifies requirements for compostable plastics in industrial facilities. Products meeting this standard must demonstrate at least 90% biodegradation within 180 days and leave no toxic residues.

EN 13432: This European standard requires products to biodegrade at least 90% within six months under industrial composting conditions, with no negative impact on compost quality.

AS 4736: The Australian standard for industrial compostability, which includes additional ecotoxicity testing to ensure the safety of resulting compost for plant growth.

AS 5810: Specifically designed for home composting systems, this standard requires products to biodegrade at least 90% within 180 days at lower temperatures typical of backyard compost piles.

These standards evaluate multiple criteria including biodegradation rate, disintegration into particles smaller than 2mm, chemical analysis for heavy metals and fluorine content, and ecotoxicity testing to ensure the resulting compost supports healthy plant growth.

Industrial vs. Home Compostable Bags

A crucial distinction exists between industrial and home compostable bags, each designed for specific disposal environments:

Industrial Compostable Bags: These products require the controlled conditions found in commercial composting facilities, including temperatures of 55-60°C, specific moisture levels, and regular aeration. While they offer superior strength and durability, their effectiveness depends entirely on access to appropriate industrial composting infrastructure.

Home Compostable Bags: Engineered to decompose under the variable conditions typical of backyard composting systems, these bags must demonstrate biodegradation at temperatures as low as 20-30°C. They represent a more accessible option for consumers but may require longer decomposition periods and specific environmental conditions.

Applications and Practical Uses

Compostable bags serve diverse applications across multiple sectors:

Food Waste Collection: Kitchen compost bin liners and food scrap bags represent one of the most common uses, allowing consumers to collect organic waste without creating additional plastic contamination.

Retail and Shopping: Many retailers now offer compostable shopping bags as an alternative to single-use plastic bags, though proper disposal infrastructure remains essential for environmental benefits.

Agricultural and Horticultural: Compostable mulch films and plant pots eliminate the need for plastic removal after harvest, reducing labor costs and environmental impact.

Food Packaging: Specialized compostable films and pouches provide barrier properties necessary for food preservation while maintaining compostability.

Environmental Impact and Considerations

While compostable bags offer significant environmental advantages over conventional plastics, their effectiveness depends heavily on proper disposal infrastructure and consumer behavior. When correctly composted, these bags contribute to circular economy principles by converting organic waste into valuable compost that can improve soil health and reduce the need for chemical fertilizers.

However, if compostable bags end up in landfills, they may not decompose as intended due to the anaerobic conditions typically found in such environments. Additionally, when mixed with conventional plastic recycling streams, compostable bags can contaminate the recycling process, potentially rendering entire batches of recycled plastic unusable.

The Future of Compostable Bags

As technology advances and production costs decrease, compostable bags are likely to play an increasingly important role in sustainable waste management. Ongoing research focuses on developing new materials with improved performance characteristics, expanding home compostability options, and creating closed-loop systems that ensure proper collection and processing of compostable materials.

The success of compostable bags ultimately depends on coordinated efforts between manufacturers, policymakers, waste management facilities, and consumers. Education about proper disposal methods, investment in composting infrastructure, and clear labeling standards will be crucial for realizing the full environmental benefits of these innovative products.

In conclusion, compostable bags represent a significant step forward in sustainable packaging technology, offering genuine environmental benefits when properly produced, used, and disposed of. As we continue to seek solutions to the global plastic pollution crisis, these bio-based alternatives provide a viable pathway toward more sustainable consumption and waste management practices.