Apparel packaging is the coordinated system of designing, selecting and producing containers, wrappers, boxes, mailers, tags, labels and ancillary graphic material that prepare clothing and footwear products for storage, handling, distribution, retail display and, increasingly, for the “unboxing” moment that ends the e-commerce journey. Far from being an after-thought, it is a multi-functional interface that simultaneously protects the garment, conveys brand values, satisfies regulatory and logistical requirements and influences the consumer’s willingness to repurchase. In 2025 the discipline sits at the intersection of materials science, marketing psychology, supply-chain analytics and sustainability engineering, making it one of the fastest-evolving segments inside the USD 1.1 trillion global fashion industry.

Contents [hide]

- 1 1. Functional Scope: More Than a Box

- 1.1 1.1 Physical Protection

- 1.2 1.2 Logistical Efficiency

- 1.3 1.3 Regulatory Compliance

- 2 2. Material Landscape 2025

- 2.1 2.1 Paper & Board

- 2.2 2.2 Recycled Plastics

- 2.3 2.3 Bio-polymers & Composites

- 2.4 2.4 Textile-to-Textile Packaging

- 3 3. Structural Formats

- 3.1 3.1 Folding Cartons

- 3.2 3.2 Flexible Mailers

- 3.3 3.3 Rigid Luxury Boxes

- 3.4 3.4 Multi-use Systems

- 4 4. Surface Graphics & Printing Technologies

- 5 5. Sustainability Metrics & Design Rules

- 5.1 5.1 Life-Cycle Assessment (LCA)

- 5.2 5.2 Design-for-Recycling Checklist (2025 PPWR)

- 5.3 5.3 Carbon Accounting

- 6 6. Consumer Psychology & the Unboxing Experience

- 7 7. Technology Integration: Smart Packaging

- 8 8. Supply-Chain Strategy 2025

- 8.1 8.1 Near-Shoring & Micro-Fulfilment

- 8.2 8.2 Vendor Scorecards

- 9 9. Future Outlook

- 10 Conclusion

1. Functional Scope: More Than a Box

1.1 Physical Protection

Textiles are vulnerable to moisture, UV light, abrasion, compression and biological attack. Apparel packaging must therefore provide:

1. Barrier films or coatings that keep relative humidity below 65 % to inhibit mould.

2. Anti-slip inserts or tissue that prevent fibre abrasion during multi-modal transport.

3. Tamper-evident seals that reduce shrinkage in high-theft categories such as denim and premium sneakers.

1.2 Logistical Efficiency

Garments are rarely shipped directly from sewing room to consumer. Instead they move through distribution centres, cross-docking hubs, dark stores and parcel lockers. Packaging engineers therefore design for:

1. Cubic optimisation: mailers that fold flat to 2 mm but expand to 40 mm avoid the “air freight tax” that can add 8–12 % to landed cost.

2. RFID and NFC integration: corrugated shipper cases with embedded RFID antennas allow 300-unit bulk reads in <3 s, cutting inventory labour by 35 % .

3. Automated handling: die-cut finger holes and 90-degree angles enable robotic arms to achieve >1 000 picks hr⁻¹ in third-party logistics (3PL) facilities.

1.3 Regulatory Compliance

The EU Packaging and Packaging Waste Regulation (PPWR) entering into force in 2025 mandates that all textile packaging be recyclable or reusable by 2030 and sets design-for-recycling criteria for flexible plastics. California’s SB 343 requires the “chasing arrows” symbol to be removed from any component that is not actually recycled at >60 % statewide. Apparel brands must therefore generate packaging specifications that satisfy both the “Essential Requirements” of the EU Directive and the Federal Trade Commission “Green Guides” in the United States.

2. Material Landscape 2025

2.1 Paper & Board

Recycled paper and cardboard held 45 % of the apparel packaging material market in 2024 and remain the default for e-commerce boxes and luxury rigid set-up cartons . Innovations include:

1. Barrier-coated Kraft: a micro-fibrillated cellulose (MFC) layer that delivers oxygen transmission rates (OTR) <0.2 cc m⁻² day⁻¹, eliminating the need for polyethylene liners.

2. Hemp-reinforced board: 20 % hemp fibre increases ring-crush strength by 18 % while reducing grammage 12 %, allowing a net weight saving of 3.5 g per mailer.

2.2 Recycled Plastics

rPET mailers are projected to grow at a double-digit CAGR through 2034 . Advanced chemical recycling (methanolysis) now yields food-grade rPET that can be extruded into 50 µm films with 120 % dart-impact strength versus virgin PET. Brands such as Patagonia and Zara have committed to 100 % rPET polybags by 2026.

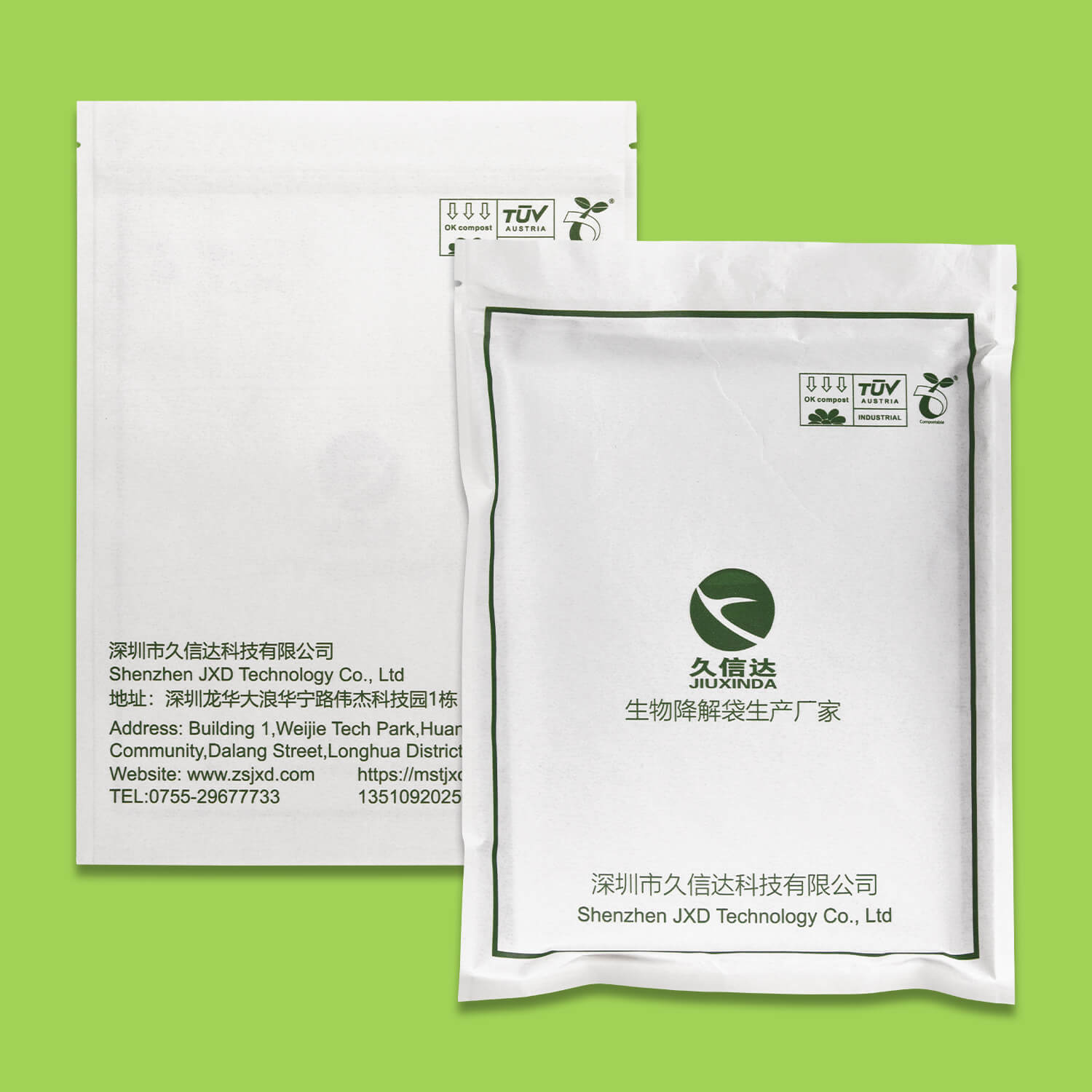

2.3 Bio-polymers & Composites

1. PHA (polyhydroxyalkanoate) derived from sugar-cane waste biodegrades in marine environments within 24 months and has heat-seal initiation temperature 20 °C lower than LDPE, enabling 8 % energy savings on VFFS lines.

2. Mycelium foam grown in 7 days from agricultural waste replaces expanded polystyrene (EPS) for premium footwear inserts and can be home-composted within 30 days .

2.4 Textile-to-Textile Packaging

Start-ups such as Circular Systems convert pre-consumer cotton waste into spun-bond non-woven mailers that are chemically identical to the garment inside, creating a mono-material loop that can be recycled together.

3. Structural Formats

3.1 Folding Cartons

Used for lingerie, shirts and knitwear, these boxes now feature “living hinges” made from 100 % board (no plastic tape) and can be erected in 1.2 s on high-speed equipment while still supporting 5 kg compression.

3.2 Flexible Mailers

The fastest-growing format for e-commerce, mailers reduced average freight cost per shipment 28 % between 2019 and 2024. 2025 designs incorporate dual peel-strip technology that allows consumers to re-seal the same mailer for returns, cutting reverse-logistics packaging waste 40 % .

3.3 Rigid Luxury Boxes

Premium brands continue to use 2 mm rigid board wrapped in printed art paper, but now embed NFC tags under the wrap to deliver provenance data and care instructions. The tags are readable even when the box is closed, enabling “shelf-edge” storytelling in department stores.

3.4 Multi-use Systems

RePack, LimeLoop and similar providers supply durable polyester envelopes designed for 20+ cycles. Life-cycle assessments show 80 % CO₂-eq reduction versus single-use LDPE mailers when the return rate exceeds 75 %.

4. Surface Graphics & Printing Technologies

Digital inkjet accounted for 18 % of apparel packaging print volume in 2024 and is forecast to reach 30 % by 2027 . Single-pass piezo heads operating at 600 × 600 dpi with water-based inks now match the colour gamut of offset lithography while cutting make-ready waste to <5 m². Variable-data printing enables limited-edition packaging that references the wearer’s name or local weather data, driving a 15 % increase in social-media mentions according to 2025 case studies by Avery Dennison.

5. Sustainability Metrics & Design Rules

5.1 Life-Cycle Assessment (LCA)

Leading brands run cradle-to-grave LCAs that include micro-fibre release during garment washing triggered by packaging contamination (e.g., silicone-coated tissue). ISO 14021-compliant claims such as “20 % recycled content” must now be substantiated by third-party-reviewed LCA reports.

5.2 Design-for-Recycling Checklist (2025 PPWR)

1. No black carbon pigments above 5 % that would hinder NIR detection.

2. Adhesive volumes < 5 g m⁻² to ensure fibre yield ≥ 95 % in repulping.

3. Water-based barrier coatings preferred over PLA laminates where paper recycling streams are the end-of-life route.

5.3 Carbon Accounting

The Fashion Charter for Climate Action requires signatories to halve packaging-related Scope 3 emissions by 2030. This translates to a maximum of 144 g CO₂-eq per average e-commerce shipment, forcing adoption of lightweight mailers and renewable energy in converting plants.

6. Consumer Psychology & the Unboxing Experience

2025 neuromarketing studies show that opening sound (decibel level 22–25 dB) and scent (subtle cotton fragrance micro-encapsulated in varnish) increase oxytocin release and brand recall by 19 %. Matte-soft touch coatings communicate luxury, while high-gloss spot UV draws attention to sustainability icons, paradoxically increasing perceived environmental credibility 12 % even when the substrate is identical .

7. Technology Integration: Smart Packaging

1. RFID & NFC: Item-level RFID in hang-tags enables “scan-free” self-checkout in Uniqlo and Decathlon stores. NFC tags inside shoe boxes allow authentication on blockchain platforms such as Eon’s CircularID.

2. Time-Temperature Indicators (TTI): Smart inks that change colour when internal temperature exceeds 35 °C for 30 min help detect heat damage in elastane-rich activewear during last-mile delivery.

3. AR triggers: QR codes printed with phosphoresccent inks launch 3-D try-on experiences on Snapchat, reducing return rates 8 % in 2025 pilots by ASOS.

8. Supply-Chain Strategy 2025

8.1 Near-Shoring & Micro-Fulfilment

To mitigate geopolitical risk and tariff volatility, 38 % of North American apparel brands now source packaging within a 1 000 km radius of their distribution centres. Digital die-cutting tables allow print-on-demand mailers with 24 h lead time, slashing finished-goods inventory 45 %.

8.2 Vendor Scorecards

Sustainability, quality, cost and innovation are weighted 40 %, 30 %, 20 % and 10 % respectively in 2025 procurement tenders. Suppliers must submit ISO 17029–compliant validation of recycled content claims and provide real-time production data via API to brand PLM systems.

9. Future Outlook

1. Edible Packaging: Start-ups are piloting rice-b starch films impregnated with natural antioxidants that dissolve in warm water and can be consumed, targeting sample swatches and accessory packaging.

2. 3-D Printed Custom Fit: HP’s Molded Fiber Tooling 2.0 enables on-demand embossing that matches the garment’s silhouette, eliminating void fill and creating Instagram-ready “shadow” reveals.

3. AI-Driven Design: Generative algorithms trained on 50 000 LCA datapoints propose mailer dimensions that minimise material and freight simultaneously, yielding average 7 % cost savings in early adopters such as Levi’s .

Conclusion

Apparel packaging in 2025 is no longer a disposable commodity but a strategic asset that unites protection, compliance, marketing and circular-economy objectives. Brands that master the emerging toolkit—bio-based barriers, digital print personalisation, smart sensors and data-driven optimisation—will convert the last square centimetre of packaging into competitive advantage while meeting the industry’s 2030 climate commitments.