Compostable plastic packaging bags are a class of bioplastic films engineered to disintegrate under composting conditions into carbon dioxide, water and biomass, leaving no visible fragments or ecotoxic residues. Unlike conventional polyethylene, they are manufactured from renewable feedstocks—most commonly polylactic acid (PLA), polybutylene adipate terephthalate (PBAT) and thermoplastic starch (TPS)—and must meet internationally harmonised standards such as EN 13432 (EU), ASTM D6400 (USA) or AS 4736 (Australia). Certification under these standards verifies that ≥90 % of the material converts to CO₂ within 180 days at 58 ± 2 °C in an industrial composting environment, while the remaining biomass passes ecotoxicity tests on plants, earthworms and soil micro-organisms .

Contents

- 1 1. Material composition and molecular design

- 2 2. Industrial vs. home-compostable grades

- 3 3. Performance in the supply chain

- 4 4. End-of-life pathways and environmental benefits

- 5 5. Standards, policy drivers and market outlook

- 6 6. Design-for-composting guidelines

- 7 7. Limitations and mitigation strategies

1. Material composition and molecular design

PLA provides stiffness and optical clarity but is brittle and hydrolyses slowly below 50 °C; PBAT contributes flexibility and rapid biodegradation; TPS acts as a cost-reducing, compost-accelerating filler. By co-extruding or blending these polymers in ratios such as PLA/PBAT 60:40 or PLA/PBAT/TPS 45:30:25, converters tune mechanical properties (tensile strength 25–45 MPa, elongation 150–350 %) while guaranteeing complete microbial assimilation once the carbon backbone is cleaved by esterases and lignocellulolytic enzymes .

2. Industrial vs. home-compostable grades

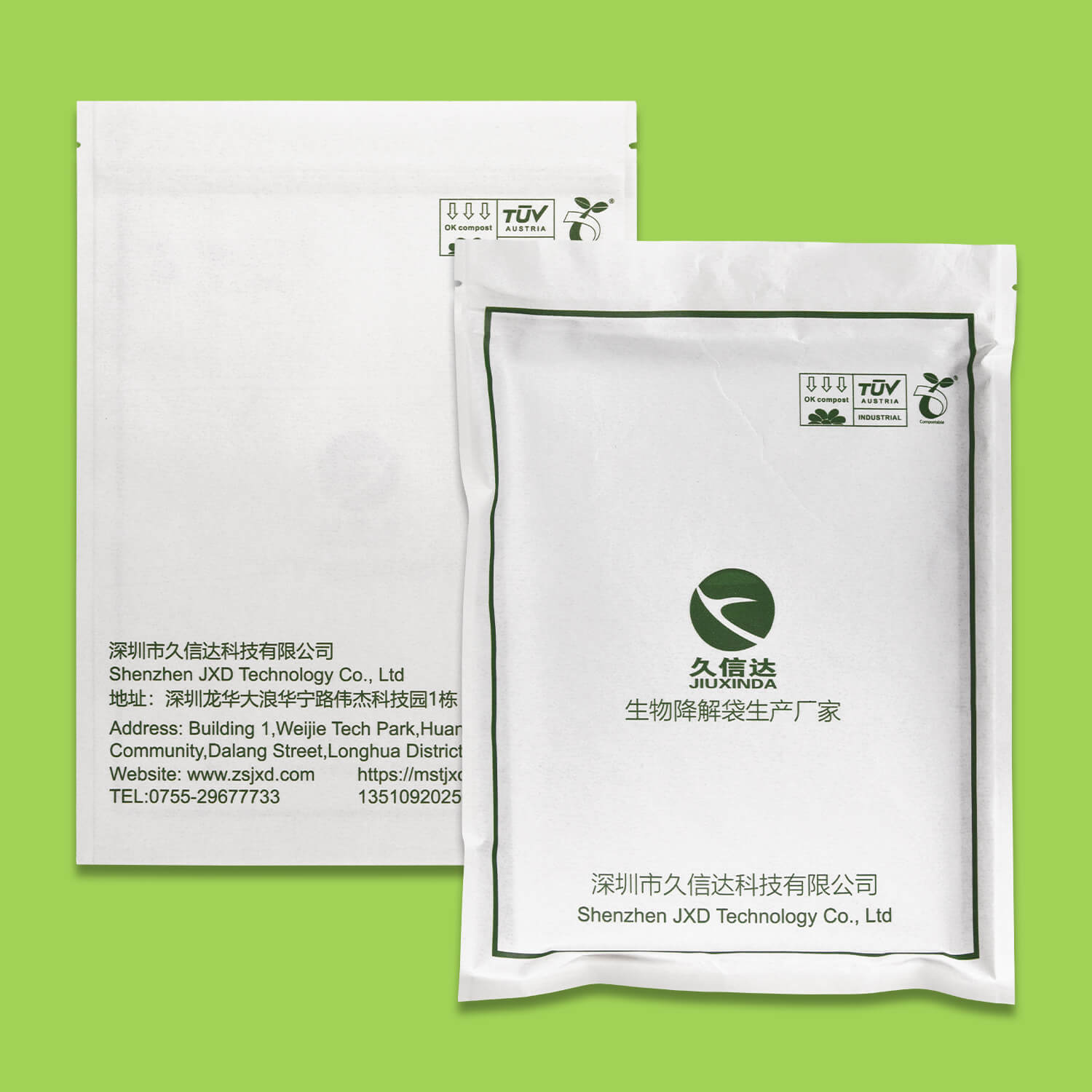

Industrial-grade films carry the “Seedling” or DIN-Geprüft logo and require the sustained thermophilic temperatures (55–60 °C) and forced aeration provided by municipal or in-vessel composters. Home-compostable variants, certified to NF T51-800 or AS 5810, incorporate aliphatic-aromatic co-polyesters with lower activation energy, enabling mineralisation at 20–30 °C within 6–12 months . Mislabelling or “green-washing” is avoided only when the corresponding certification mark (e.g., OK compost HOME) is printed on each bag together with a 2-D code linking to the certificate .

3. Performance in the supply chain

Despite a density 8–10 % higher than LDPE, compostable mailers and garment bags (15–60 µm) exhibit comparable puncture resistance (≥5 N) and heat-seal strength (≥15 N/15 mm), allowing direct substitution on existing VFFS or mailer-bag lines . Breathability (WVTR 300–600 g m⁻² day⁻¹) reduces condensation and mould in fresh-produce pouches, extending shelf-life of leafy greens by 1–2 days compared with perforated PE . Printable surface energy (>38 dyn cm⁻¹) accepts water-based inks without corona treatment, enabling high-resolution QR codes and sustainability messaging.

4. End-of-life pathways and environmental benefits

When captured together with source-separated food or green waste, compostable bags increase organics diversion rates by 5–15 % because householders use the bag as a liner rather than rejecting wet, messy organics . Life-cycle assessment (LCA) shows that replacing 1 t of fossil PE with PLA/PBAT film saves 1.8–2.1 t CO₂-eq if the bag is composted and the resulting compost offsets mineral fertilisers . Microplastic formation is negligible: particles >100 µm decline to <0.5 % of initial mass within 90 days under industrial conditions .

5. Standards, policy drivers and market outlook

The EU Packaging and Packaging Waste Directive (PPWD) explicitly recognises EN 13432-certified carrier bags as a compliant route to achieve the 80 % reduction in single-use plastic bag consumption mandated by 2025 . Similar bans in California, New York and a growing number of Asian cities create a regulatory pull that is forecast to raise global demand for compostable packaging films from 0.9 Mt in 2023 to 2.5 Mt by 2030, a CAGR of 15 %. Price parity with recycled PE is expected by 2028 as lactic-acid capacity expands in Thailand, China and the U.S. Midwest .

6. Design-for-composting guidelines

- Use mono-material films or certified adhesive layers to avoid contamination.

- Print only with compostable inks (no heavy-metal pigments).

- Provide clear colour coding (green or beige) and the word “COMPOSTABLE” ≥2 mm high.

- Avoid metallised or aluminium layers; use high-white PLA for barrier needs <1 g m⁻² day⁻¹.

- Specify shelf-life ≤12 months at <25 °C/60 % RH to preclude premature embrittlement .

7. Limitations and mitigation strategies

Compostable bags do not degrade appreciably in landfills or marine environments; therefore, coupling their introduction with robust organics-collection infrastructure is essential. Retail staff and consumers must be trained to distinguish “COMPOSTABLE” from “BIODEGRADABLE” logos to prevent recycling-stream contamination. Finally, moisture sensitivity (Tg of PLA ~55 °C) means transport above 40 °C can seal layers together—mitigated by adding 5 % bio-based plasticiser or using opaque cartons during summer shipments .

In summary, compostable plastic packaging bags are scientifically formulated, standards-verified films that turn post-consumer waste into a valuable soil amendment while reducing fossil-carbon use and plastic leakage. Their successful deployment hinges on correct resin formulation, clear certification labelling and—critically—an accessible organic-waste collection route that routes the bag, together with its food-waste content, to a well-managed composting facility.