Polyethylene (PE) bag packaging refers to the use of bags made from polyethylene—a thermoplastic polymer derived from ethylene—for the containment, protection, and distribution of goods. As one of the most widely produced and utilized plastics globally, polyethylene offers a unique combination of flexibility, durability, chemical resistance, and cost-effectiveness, making it an ideal material for packaging across a broad spectrum of industries.

Contents [hide]

- 1 Understanding Polyethylene (PE)

- 2 Manufacturing Process of PE Bags

- 3 Applications of PE Bag Packaging

- 3.1 1. Food Packaging

- 3.2 2. Retail and Consumer Goods

- 3.3 3. Industrial and Chemical Packaging

- 3.4 4. Medical and Laboratory Use

- 3.5 5. Agriculture

- 4 Environmental Considerations

- 5 Conclusion

Understanding Polyethylene (PE)

Polyethylene is synthesized through the polymerization of ethylene monomers and exists in several forms, the most common being low-density polyethylene (LDPE) and high-density polyethylene (HDPE). Each type exhibits distinct physical properties:

- LDPE is characterized by its low density, high flexibility, and transparency. It is commonly used for lightweight applications such as food packaging, garment bags, and general-purpose storage.

- HDPE, on the other hand, is denser, more rigid, and offers greater tensile strength. It is often used for heavier-duty applications like grocery bags, industrial liners, and shipping sacks.

Another variant, linear low-density polyethylene (LLDPE), combines the flexibility of LDPE with enhanced strength and puncture resistance, making it suitable for more demanding packaging needs such as trash bags and stretch films.

Manufacturing Process of PE Bags

The production of PE bags typically begins with blown film extrusion, a process in which polyethylene pellets are melted and extruded through a circular die to form a thin, continuous tube of plastic. This tube is then inflated with air to achieve the desired film thickness and cooled. The resulting film is flattened, cut, and sealed into bags of various sizes and configurations.

Depending on the intended application, PE bags can be manufactured with additional features such as:

- Zipper closures for resealability

- Gussets or block bottoms for improved capacity and stacking

- Perforations or vent holes for breathability

- Custom printing for branding or product information

Applications of PE Bag Packaging

PE bags are ubiquitous in both consumer and industrial contexts due to their adaptability. Key application areas include:

1. Food Packaging

PE bags are widely used in the food industry due to their non-toxic, odorless, and moisture-resistant properties. LDPE bags are commonly used for bread, produce, and frozen foods, while HDPE bags are used for bulk food items and takeaway packaging.

2. Retail and Consumer Goods

From shopping bags to garment covers, PE bags offer a lightweight and economical solution for retail packaging. Their transparency and printability also make them ideal for branding and product visibility.

3. Industrial and Chemical Packaging

PE bags are used to package chemicals, powders, and granular materials. Their chemical resistance and ability to be heat-sealed make them suitable for containing hazardous or fine substances safely.

4. Medical and Laboratory Use

In healthcare settings, PE bags are used for specimen collection, medical waste disposal, and sterile packaging. Their impermeability and compatibility with sterilization processes are critical in maintaining hygiene and safety.

5. Agriculture

PE bags are used for packaging seeds, fertilizers, and animal feed. Their durability and resistance to environmental conditions make them suitable for outdoor storage and transport.

Environmental Considerations

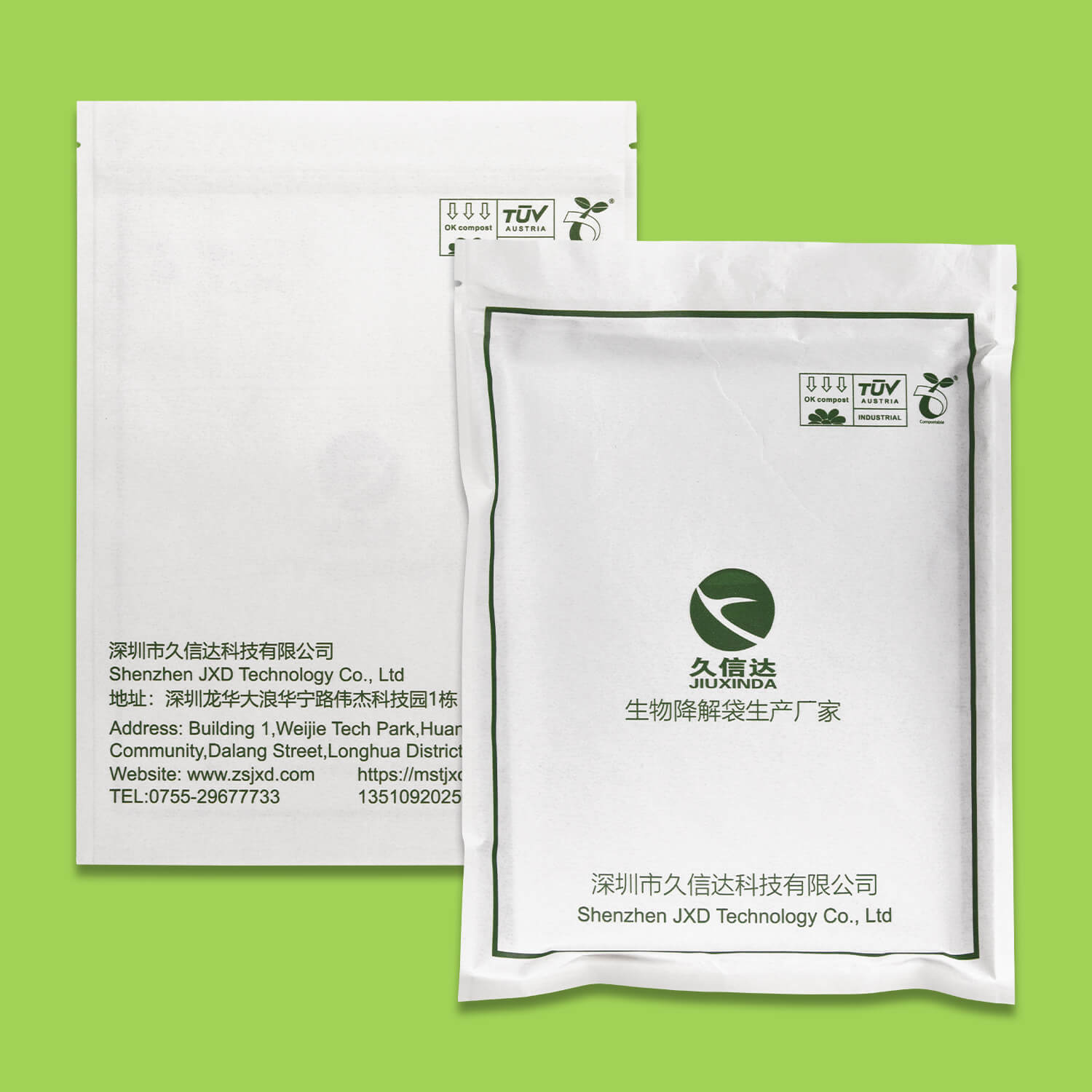

While PE bags offer numerous functional advantages, their environmental impact has become a growing concern. Polyethylene is non-biodegradable, and improper disposal can lead to long-term pollution. However, PE is recyclable, and many manufacturers are now producing bio-based or biodegradable alternatives to traditional PE films.

Efforts to improve sustainability include:

- Incorporating recycled PE (rPE) into new bags

- Reducing film thickness without compromising strength

- Promoting reusable PE bags over single-use variants

- Educating consumers on proper recycling practices

Conclusion

PE bag packaging is a cornerstone of modern packaging solutions, offering unmatched versatility, protection, and cost-efficiency. From food safety to industrial containment, polyethylene bags serve a vital role in global supply chains. As sustainability becomes increasingly important, the industry continues to innovate, balancing performance with environmental responsibility. Understanding the properties, applications, and environmental implications of PE bags is essential for making informed packaging decisions in today’s market.