Introduction

A shirt is deceptively delicate. Folded incorrectly, it arrives a crumpled mess; packaged poorly, it can absorb moisture, pick up warehouse odours, or be pierced by a stray box-cutter. At the same time, the parcel is often the first physical touch-point a customer has with an e-commerce brand. It must therefore do three things simultaneously: protect the product, control cost, and deliver a brand experience strong enough to survive on TikTok. This article walks through the decision-making framework that experienced fulfilment managers, apparel start-ups, and even individuals mailing a single gift shirt should use to determine the “best” packaging for shipping a shirt.

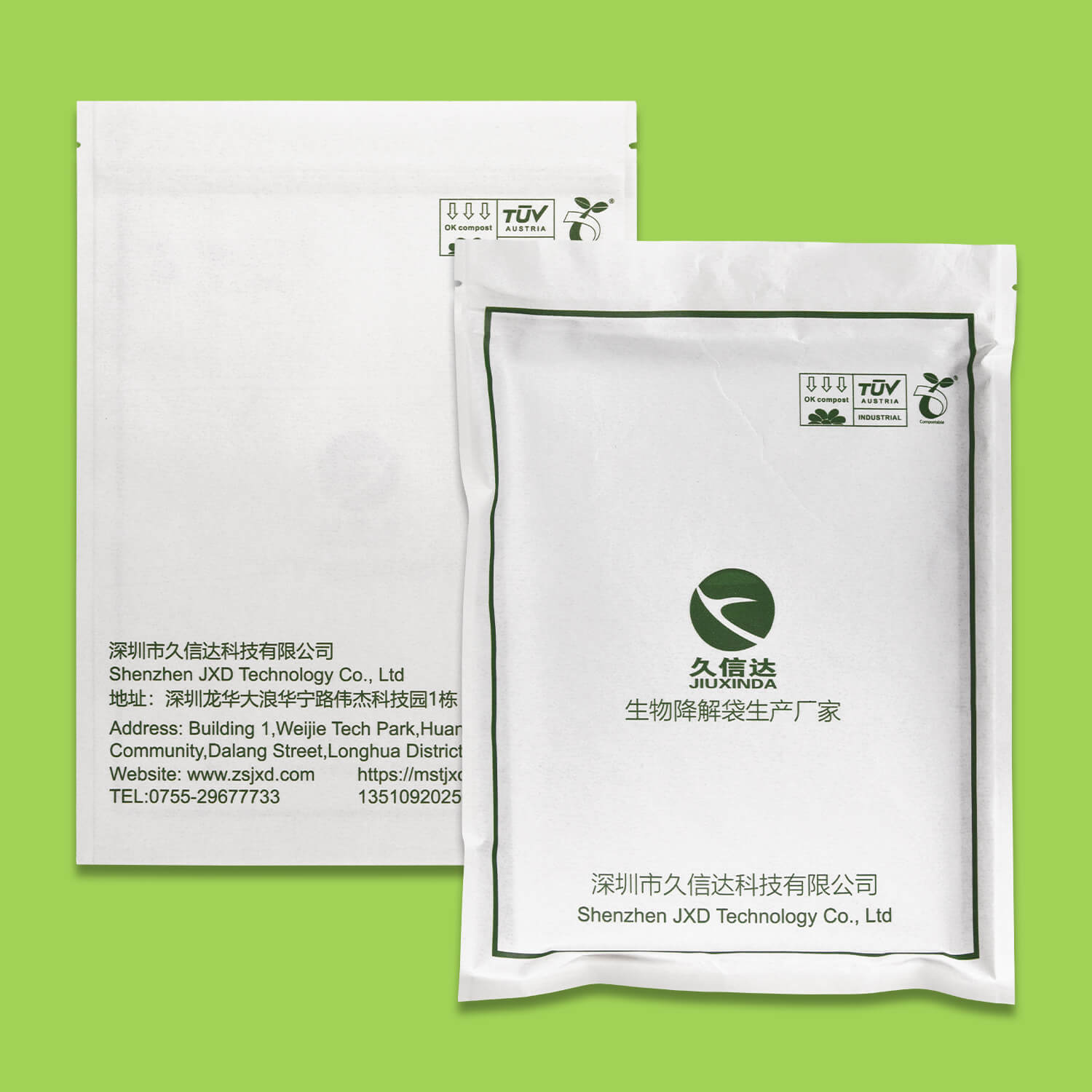

shirt packaging bags

shirt packaging bags

- Define “Best” – Five Performance Dimensions

Before comparing mailers, it is useful to translate the word “best” into measurable attributes:- Protection: Keeps the shirt clean, dry, and wrinkle-free through multi-modal transit (parcel sort rollers, van floors, apartment lobbies).

- Cube optimisation: Minimises billable weight (actual vs. dimensional) with carriers.

- Sustainability: Meets corporate ESG targets, regional Extended Producer Responsibility (EPR) laws, and consumer sentiment.

- Brand theatre: Creates an “unboxing” moment that is camera-ready and shareable.

- Cost at scale: Material + labour + freight, landed per order, usually quoted in cents—not dollars—at volume.

Each shipper will weight these factors differently. A luxury fashion label may sacrifice cost for theatre; a print-on-demand store may reverse those priorities. The remainder of this article maps common shirt-packaging formats against the five dimensions so you can choose the point on the curve that matches your strategy.

- Step 1 – Inner Protection Layer

Regardless of outer packaging, the shirt itself needs a primary barrier.

A. Recycled-content polybag (0.0015–0.002 mil)

Cost: US $0.03–0.05 in volume.

Protection: Excellent dust, odour, and moisture barrier; anti-static versions reduce lint attraction.

Sustainability: LDPE #4 is store-drop-off recyclable; 100 % PCW versions exist but cost ~20 % more.

B. Compostable PLA or corn-starch film

Certified EN 13432 / ASTM D6400 films perform identically to poly during transit but industrial-compost at end-of-life.

Cost: US $0.07–0.10; must be stored <50 % RH to prevent premature brittleness.

C. Acid-free tissue + paper belly-band

Classic luxury touch; adds <8 g to parcel weight.

Pair with FSC-certified paper and soy inks to satisfy most green claims.

Rule of thumb: If the shirt sells above US $40 MSRP or is gifted, add tissue and a belly-band; otherwise the recycled polybag is the economical default.

- Step 2 – Outer Packaging Options

3.1 Poly Mailer (lightweight, weather-proof)

Construction: Co-extruded PE outer, sometimes with interior bubble layer.

Sizes for shirts: 6 × 9 in (baby/child), 10 × 13 in (adult folded once), 12 × 15.5 in (adult folded twice + extra buffer).

Protection score: 8/10 against moisture, 5/10 against crush wrinkles.

Cube optimisation: Excellent—conforms to contents, so dimensional weight rarely triggers.

Sustainability: Choose 50–100 % PCW or “poly-to-poly” recyclable versions; print “Store drop-off recyclable” in 12 pt+ font to meet FTC Green Guides.

Branding: Full-bleed flexo or HD digital print available at 500-piece MOQs; matte finish scuff-resistant.

Cost: US $0.12 plain, US $0.26 custom 1C, volume 10 k.

Best fit: DTC fashion basics, subscription boxes, fulfilment centres chasing

3.2 Paper Mailer (Kraft or White)

Construction: 200–250 gsm Kraft outer + interior honeycomb or padded liner; peel-and-seal strip.

Sizes: Similar to poly; 11 × 15 in most common.

Protection: 7/10 moisture (brief exposure), 8/10 crush; liner prevents fibre rub-off on light colours.

Sustainability: kerbside recyclable; natural fibre version can be home-composted.

Branding: Excellent—litho or flexo outside, inside print available for “surprise” graphics.

Cost: US $0.32–0.42 blank, add US $0.08 per colour.

Best fit: Eco-centric brands, EU/UK markets with plastic-reduction pledges, price-point US $35–70.

3.3 Corrugated Mailer (E- or B-flute)

Construction: Single-wall die-cut “book-fold” or “one-piece folder”; 32 ECT test.

Sizes: 10 × 8 × 2 in fits 1–2 shirts; 12 × 9 × 3 in fits 3–4 shirts plus inserts.

Protection: 10/10 crush, puncture, and stacking; insert dividers eliminate fold migration.

Cube optimisation: Worst—fixed footprint can push parcel into 2 lb+ dim-weight tier.

Sustainability: 90–100 % PCW available; printed “please reuse” boosts circularity stats.

Branding: High-graphic direct print or litho-label; spot UV, foil, emboss all possible.

Cost: US $0.55 plain, US $1.10 full-coverage 4C, volume 5 k.

Best fit: High-value items, gift editions, or multi-piece bundles needing insert real-estate.

3.4 Rigid Stay-Flat Mailer (chipboard)

Construction: 24–28 pt clay-coated newsback; corner guards.

Protection: 9/10 crush; zero fold memory.

Sustainability: Curbside recyclable; not suitable for wet climates without overwrap.

Cost: US $0.60–0.70.

Best fit: Graphic tees with screen-printed signatures, artist collaborations—prevents crease across artwork.

3.5 Cylinder/Tube

Construction: Spiral-wound Kraft, 3-ply, metal or plastic end-caps.

Method: Roll shirt around 2 in tissue-covered collar core; slide into tube.

Protection: 10/10 wrinkle; 6/10 moisture (needs interior poly sleeve).

Cube optimisation: Dimensional weight killer—USPS often classifies as “non-machinable” surcharge.

Branding: High novelty; perfect for unboxing reels.

Cost: US $1.20–1.50 plus labour to roll.

Best fit: Limited drops, influencer PR mailers, price-point >US $80.

- Ancillary Components – When & Why

Tissue paper: Adds 4–6 g; choose 17 gsm FSC, acid-free. Printed tissue increases perceived value 15–20 % in consumer surveys.

Branded sticker: Poly or paper, US $0.02; seals tissue, doubles as tamper-evidence.

Thank-you / care card: 4 × 6 in 14 pt cardstock, US $0.04; include QR code for reorder or social hashtag.

Discount code on outer box: Drives 8–12 % second-purchase lift within 60 days.

Fragrance strip: Avoid—triggers allergic return claims; major carriers forbid liquid scent in air transit.

- Decision Matrix (1 shirt, USA domestic, 1–8 oz final weight)

| Evaluation Dimensions | Poly 10 × 13 | Paper Mailer | E-Flute Box | Tube |

|---|---|---|---|---|

| Protection | 7 | 8 | 10 | 10 |

| Dim Weight Risk | 1 | 2 | 4 | 5 |

| Material Cost | 1 | 3 | 5 | 5 |

| Eco Optics | 2 | 1 | 1 | 2 |

| Brand Theatre | 2 | 2 | 4 | 5 |

(1 = best score, 5 = worst)

Conclusion: Poly mailer wins on cost/cube; paper mailer balances eco and price; box or tube justified only when brand theatre or giftability commands price premium.

- Packing Workflow – How to Fold & Insert

- Launder and steam-shirt; lint-roll dark colours.

- Button top button; lay face-down on clean table.

- Fold sides 1/3 in toward centre; fold sleeves back to make rectangle.

- Fold tail up 1/3, then fold top down—finished footprint ≈ 9 × 7 in.

- Slide into inner poly or compostable bag; squeeze excess air.

- Place belly-band or tissue wrap around folded shirt; secure with 1 in branded sticker.

- Insert into mailer; peel seal, press 2 s across flap, 2 s each edge.

- Add shipping label on largest face; no overlap on seams; place duplicate slip inside.

- For boxes: cushion with 30 gsm crinkle or 70 gsm Kraft paper to inhibit movement.

- Weigh and measure; verify dim-weight divisor (USPS 166, UPS/FedEx 139) before purchasing postage.

- International & Regulatory Notes

- CN22/CN23 customs forms: Contents = “Men’s cotton T-shirt, HS 6109.10”; value in USD; attach in clear pouch.

- EU Packaging Regulation (PPWR) 2024: >40 % recycled content in plastic mailers by 2030; paper alternatives exempt.

- IATA: Avoid silica-gel packets >2 g—they are classed as “moisture control devices” requiring MSDS in some jurisdictions.

- Sustainability Checklist

☑ Specify % PCW and recyclability claim on mailer (FTC-compliant).

☑ Use right-sized packaging to cut void fill >90 %.

☑ Consolidate SKUs into two mailer sizes to raise purchase volume and reduce unit cost.

☑ Ask supplier for LCA data; many mills now provide cradle-to-gate CO₂ per 1 000 mailers.

☑ Offer customer “take-back” via poly-to-poly store drop-off; include URL on print.

- Cost-Control Levers

- Combine orders: Average 1.3 shirts per parcel can raise margin 4–6 % by saving duplicate mailers.

- Zone skipping: Ship cartons of pre-packed mailers to 3PLs near demand clusters; reduce final-mile zone count.

- Freight rate index: Poly mailers track LDPE resin prices (CME); lock quarterly contracts when resin falls 5 %+.

- Labour: Auto-baggers with print-and-apply modules can cut 14 s per order; payback ~8 months at 800 orders/day.

- Key Takeaways

- For most single-shirt shipments, a 100 % recycled content poly mailer remains the optimal balance of protection, postage cost, and fulfilment speed.

- Upgrade to paper mailer or box only when brand positioning or regulatory constraints outweigh the 25–40 % cost uplift.

- Inner sleeve (recycled poly or compostable film) is non-negotiable: it is the cheapest insurance against moisture and odour.

- Wrinkle prevention is achieved by disciplined folding and right-sized void fill, not by expensive outer packaging.

- Treat the parcel as media: a printed tissue, a QR-linked story, or a clever dieline can generate user-generated content worth more than the incremental packaging spend.

By rigorously mapping your product price-point, customer expectations, and sustainability commitments against the matrix above, you will land on a packaging specification that is—for your specific definition—the “best” way to ship a shirt.