In the apparel industry, bags are not only a tool used to load clothing, but also an important carrier of brand image. A well-designed and produced garment bags can enhance the added value of the product, enhance the consumer’s purchasing experience, and even influence the consumer’s purchasing decision to a certain extent. Therefore, when customizing garment bags, need to consider a number of aspects to ensure that it is in function, aesthetics, environmental protection and cost to achieve the best balance.

Contents [hide]

- 1 I. Functional requirements

- 1.1 1. Size fit

- 1.2 2. Sturdy construction

- 1.3 3. Good sealing

- 2 Second, the design is beautiful

- 2.1 1. Brand image display

- 2.2 2. Color matching

- 2.3 3. Pattern design

- 3 Third, environmental factors

- 3.1 1. Material selection

- 3.2 2. Reduce waste

- 4 Cost control

- 4.1 1. Material costs

- 4.2 2. Printing costs

- 4.3 3. The relationship between quantity and cost

- 5 V. Regulations and Standards

- 5.1 1. Safety standards

- 5.2 2. Labeling requirements

- 5.3 3. Industry specifications

- 6 Customized display of clothing packaging bags

- 7 T-shirt Packaging Bags

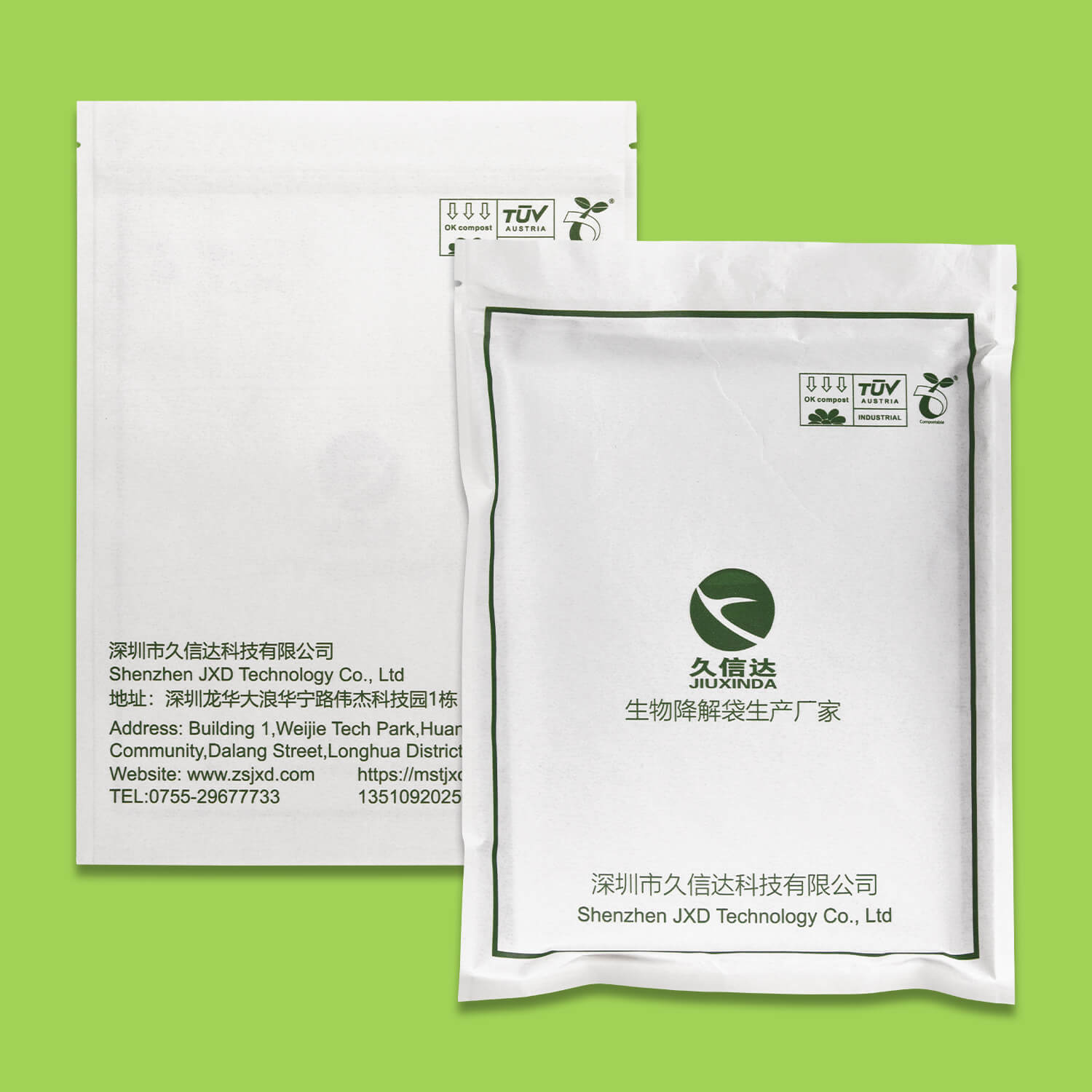

- 8 Compostable packaging bags

- 9 Ziplock Bag With Pothook

- 10 Compostable Biodegration Clothing Packaging Self-adhesive Bag

I. Functional requirements

1. Size fit

Clothing in a variety of styles and sizes, from underwear to jackets, from children’s clothing to adult clothing, the size of the bag must be able to meet the loading requirements of different garments. When customizing, the specifications of the bag should be determined according to the type and maximum size of the garment. For example, for long down jackets, the height and width of the bag needs to be large enough to ensure that the garment will fit in flat and avoid excessive squeezing that can lead to wrinkles. And for some small accessories, such as scarves and gloves, you can design smaller bags to save costs and ensure compact packaging.

At the same time, you also need to consider the opening of the bag. Some garments may need to be loaded from the top opening, while others are more suitable for opening from the side. For example, some dresses with shoulder decorations can be opened from the side to avoid damaging the decorative part.

2. Sturdy construction

The structure of the garment bag must be strong enough to withstand a certain amount of weight and pressure. In the transportation process, the bag may be subject to extrusion, collision and other external forces. If the material and structure of the bag is not strong enough, it may lead to damage to the garment. For example, bags made with low-quality plastic film may break under heavy pressure, leaving garments exposed and susceptible to dust or damage.

To enhance the firmness of the bags, you can choose materials with a certain thickness and toughness. For example, polypropylene (PP) materials have good tensile and impact resistance and are suitable for making bags for heavier garments. In addition, you can also increase the reinforcement layer at the bottom and sides of the bag, or use a double-layer structure design to improve its load-bearing capacity.

3. Good sealing

Good sealing can prevent dust, moisture and odor from entering the bag, to protect the quality of clothing. For some high-grade fabrics of clothing, such as silk, cashmere, etc., sealing is particularly important. Moisture may cause these fabrics to become moldy, discolored or deformed.

When designing bags, you can choose styles with zippers, Velcro or heat seals. Zipper bags are easy to use, seal well, and can be reused many times. Velcro bags are softer, suitable for some of the softness of the bag requirements of the garment. Heat-sealed bags are a one-time use of packaging, its sealing is the strongest, suitable for the sealing requirements of the garment is very high.

Second, the design is beautiful

1. Brand image display

The bag is an important display window of the brand image. In the design, we should fully consider the brand positioning and brand style. Brand logo is an essential element, which can help consumers quickly identify the brand. The location, size and color of the logo need to be carefully designed. For example, for high-end brands, the logo is usually placed in a conspicuous position on the bag, using the process of hot-stamping gold or silver to show the brand’s sense of luxury. While for some young and fashionable brands, the logo may adopt more lively colors and creative designs to attract the attention of young consumers.

In addition to the brand logo, elements such as the brand slogan, brand story or brand philosophy can also be added to the bags. These elements can further convey the brand’s values and enhance brand identity. For example, some brands focusing on environmental protection, can be printed on the bag “environmental fashion, from me” and other slogans, so that consumers feel the brand’s environmental philosophy.

2. Color matching

Color has an important impact on the consumer’s visual perception and purchase emotions. When choosing the color of the bag, it should be decided according to the brand style and clothing style. For some elegant and high-end brands, classic colors such as white, black, gold or silver are usually used. These colors can create a simple and atmospheric visual effect. For example, the bags of Chanel brand are in black and white as the main colors with gold logo, showing the luxury and classic of the brand.

For some lively and fashionable brands, you can boldly use bright colors, such as red, orange, blue and so on. These colors can attract consumers’ attention and create an energetic feeling. At the same time, color matching techniques can also be used, such as contrasting color matching and adjacent color matching, to make the bags more beautiful. For example, the use of blue and orange contrasting color matching can produce a strong visual impact.

3. Pattern design

Pattern design can increase the fun and artistic sense of the bag. Patterns can be abstract geometric shapes, figurative flowers, animal patterns, or brand characteristics of the iconic pattern. For example, Gucci (Gucci) brand bags often appear on its classic double G pattern, this pattern has become a symbol of the brand, so that consumers can recognize at a glance.

When designing the pattern, pay attention to the size, sparseness and arrangement of the pattern. The pattern should not be too complex, so as not to affect the overall aesthetics of the bag. At the same time, the style of the pattern should be consistent with the brand style. For example, for some retro style brands, you can use retro floral patterns; and for some modern style brands, you can use simple line patterns.

Third, environmental factors

1. Material selection

In today’s increasingly aware of environmental protection, the choice of environmentally friendly materials to make bags is crucial. Traditional plastic bags are difficult to degrade after use and can cause serious pollution to the environment. Therefore, you can consider using biodegradable plastic, kraft paper, non-woven fabric and other environmentally friendly materials.

Biodegradable plastics can decompose in the natural environment within a certain period of time, reducing the pollution of soil and water. Kraft paper is a natural, recyclable material with good air permeability and texture, suitable for making bags for some high-end garments. Nonwoven fabric is a reusable material with durable and lightweight characteristics, suitable for making bags for multiple uses.

2. Reduce waste

When customizing packaging bags, it is necessary to minimize the waste of materials. On the one hand, the design of the bags can be optimized to minimize the amount of material used under the premise of meeting functional requirements. For example, a compact size design is used to avoid the use of oversized bags.

On the other hand, the recyclability of the bags can be considered. Label the bags with recyclable symbols and use materials that are easy to recycle to make it convenient for consumers to recycle them after use. In addition, you can also encourage consumers to reuse bags, such as printed on the bag “reusable” and other words, or design some multi-functional bags, such as bags with handles, so that after use can be used as shopping bags and other purposes.

Cost control

1. Material costs

Material is the main component of the cost of bags. When choosing materials, we should try to choose cost-effective materials under the premise of ensuring quality and environmental protection. For example, the price of non-woven fabric is relatively low and has good performance, is a more affordable choice. As for some high-end brands, if they need to use special materials, such as high-grade leather or silk to make bags, they can reduce the cost by optimizing the design while ensuring the quality. For example, reduce unnecessary decorative parts, or adopt the local use of high-grade materials.

2. Printing costs

Printing is also an important part of the cost of bags. When designing bags, pay attention to the complexity of printing. Complex patterns and multi-color printing will increase printing costs. Therefore, you can try to use a simple design to reduce the color and area of printing. For example, the use of single-color or two-color printing, or the use of simple line patterns and text design can reduce costs, but also be able to maintain the beauty of the bag.

3. The relationship between quantity and cost

The quantity of customized bags also affects the cost. Generally speaking, the more customized quantity, the lower the unit cost. This is because the fixed costs of the printing and production process can be spread over more bags. Therefore, when customizing bags, the number of customized quantities should be reasonably determined according to the actual demand. If the sales volume is expected to be large, the customized quantity can be increased appropriately to reduce the unit cost. However, if the sales volume is uncertain, you can first customize a small number of bags for trial, according to market feedback and then decide whether to increase the number of customized.

V. Regulations and Standards

1. Safety standards

Clothing bags need to meet the relevant safety standards. For example, the material of the bags can not contain harmful chemicals, such as heavy metals, formaldehyde and so on. These harmful substances may cause harm to human health through skin contact or inhalation and so on. When choosing materials, make sure that they comply with national or international safety standards, such as the REACH regulation of the European Union or the CPSIA regulation of the United States.

2. Labeling requirements

In some countries and regions, bags need to be labeled with relevant labeling information. For example, the material of the bag, whether it is recyclable, production date and other information need to be clearly labeled on the bag. This labeling information can help consumers understand the use of the bag and environmental attributes, but also a necessary condition to comply with regulatory requirements.

3. Industry specifications

The apparel industry also has some common norms and standards, such as bag size standards, printing quality standards and so on. When customizing bags, it is important to follow these industry norms to ensure the quality and compatibility of the bags. For example, some e-commerce platforms have clear requirements for the size and weight of the bags, and failure to meet these requirements may result in increased transportation costs or failure to ship properly.

In summary, customized garment packaging bags are a process that requires comprehensive consideration of several factors. From functional requirements to design aesthetics, from environmental factors to cost control, to regulations and standards, every aspect is crucial. Only by balancing and optimizing these aspects can we customize garment packaging bags that are both practical and aesthetically pleasing, environmentally friendly and economical, adding value to apparel products and enhancing brand image, as well as providing consumers with a better shopping experience.